You can change the machining parameters of the CNC machine tool used to machine a model when creating a toolpath.

To change the machining parameters of a CNC machine tool:

- In the Toolpaths panel, click the toolpath you want to create.

- When you have selected a tool, click the tool's control bar to display the machining parameters.

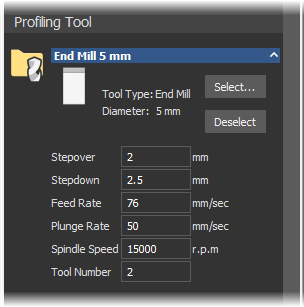

For example, if you have selected a 5mm End Mill tool in a Profiling toolpath, the tool area of the Profiling panel is as follows:

- You can now set the new machining parameters:

- Stepover — Enter the distance between adjacent machining passes.

- Stepdown — Enter a tool's maximum cutting depth. The stepdown generates multiple machining passes.

- Feed Rate — Enter the speed that the tool moves in relation to the material block.

- Plunge Rate — Enter the speed at which the tool moves in the Z direction when it plunges into the material block.

- Spindle Speed — Specify the rotational speed of the spindle. The spindle is the part of the machine tool that rotates during operation. On a mill it holds the tool in position. On a lathe it holds the material block.

- Tool Number — Enter the number you want to assign to the selected tool. This number should correspond with the position of the tool in the CNC machine's tool changer.