Supports required to steady an assembly during printing are managed using 3D Printing Structures items, which can be specified for individual assemblies or 3D Printing Platform items. This provides the flexibility to create one structure for all the parts in a platform item, or to create different structures for different parts of the job.

To create a 3D Printing Structures item:

- In the

3D Printing Platform panel, click the

Create New 3D Printing Structures

button. A

3D Printing Structures

item is added to the Project Tree.

Note: Alternatively, to create a structure for an individual item right-click the item, and select Create New 3D Printing Structures in the context menu.

button. A

3D Printing Structures

item is added to the Project Tree.

Note: Alternatively, to create a structure for an individual item right-click the item, and select Create New 3D Printing Structures in the context menu. - Select the 3D Printing Structures item in the Project Tree. The 3D Printing Structures panel is displayed.

- In the Distance from base to bottom box, enter the distance from the bottom of the part to the top of the base. Alternatively, if you are creating a structure for a 3D Printing Platform item, select Rest on platform to automatically calculate the distance between the part and the base.

- In the Base thickness box, enter the depth of the base. The base must be thick enough to support the part, and there must be sufficient space between the part and the base to create supports.

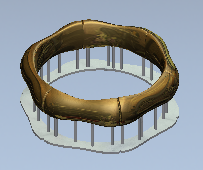

- To create an outline base, select

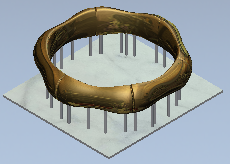

Silhouette base. To create a rectangular base, deselect

Silhouette base

and enter a value in the

Border thickness box to specify how far the base should extend beyond the edges of the part. For example:

Silhouette Base selected

Silhouette Base deselected

- Use the buttons in the

Contact Points and Supports section, to create and manage contact points and supports. Click:

to create supports.

to create supports.

to automatically generate contact points.

to automatically generate contact points.

to create supports from contact-point groups.

to create supports from contact-point groups.

to create a contact-point group.

to create a contact-point group.

to load contact-point groups from a template.

to load contact-point groups from a template.

to display the

Contact Points Template Library panel.

to display the

Contact Points Template Library panel.

to display the

Support Library panel.

to display the

Support Library panel.