Use the options in the Cutting Depth area to specify the cutting depths, tolerance, and vector-machining options.

- Start Depth — Enter the depth (Z) from the surface of the material at which you want to begin machining.

- Finish Depth - Enter the final depth (Z) for the tool.

- Tolerance - Enter a value in the box to specify how closely the tool follows the shape of the selected vectors. Entering excessively small values increases the size of the toolpath file and slows down calculation and machining times.

- Vectors are on surface — If selected, the vectors are assumed to define the top of the engraved area. If deselected, the vectors are assumed to define the area at the bottom of the engraved area. For straight sided tools, this option makes no difference, but for angled tools more material will be removed if this option is deselected.

Note: Corner sharpening is only available if Vectors are on surface is selected.

- Outer vectors are boundary — If selected, the outer vectors of the selection are used only as limits for the tool movement. In addition, no corner sharpening moves are performed on the outer boundary.

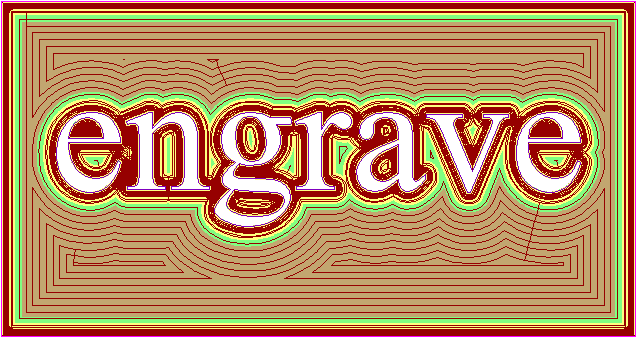

Outer vectors are boundary deselected

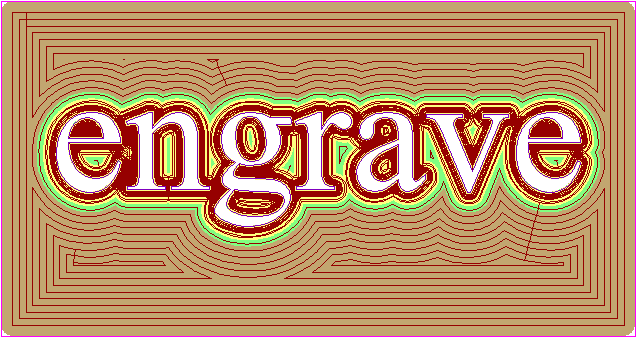

Outer vectors are boundary selected

End Mill 3 mm

End Mill 3 mm

Conical 0.25 Flat - 15 degrees

Conical 0.25 Flat - 15 degrees

Conical 0.125 Flat - 10 degrees

Conical 0.125 Flat - 10 degrees

- Offset end mills for engraving tools — If selected, any end-mill tools are offset to ensure the following engraving tools are able to machine an angled wall. The end-mill tools are offset for the widest angle tool which is cutting a full depth.