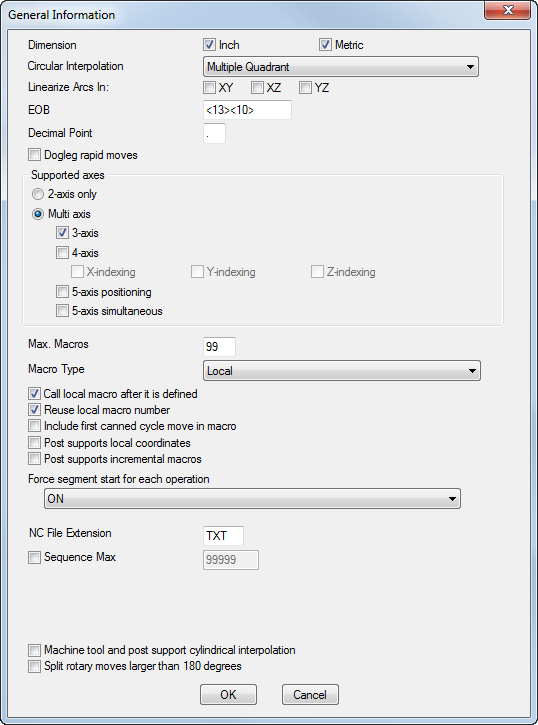

The General Information dialog enables you to specify the output program format.

You can specify the following parameters:

Dimension — Selects whether the post is in Inch or Metric units, or both. We recommend posts that support both units.

Circular Interpolation — Select the programming format on the CNC for which the post processor is being built. You can choose Multi-Quadrant, Single Quadrant, or Not Supported option, as appropriate. For example, if the Numerical Control cannot drive an arc across a quadrant line (plus or minus X and Y axes), then select Single Quadrant circular interpolation. When circular interpolation is turned off in post, then wrap tolerance is used to control fineness of toolpath.

Linearize Arcs In — Select which plane(s) on the machine allow linearization.

Decimal point — Enter the decimal point character, for example: (US and UK) or (Europe).

Dogleg rapid moves — This setting only affects the simulation. When the option is selected, both simulated axes move at the maximum rate during a rapid move from point A to point B until one of the moves is completed. The machine then proceeds to B with the other axis continuing in a straight line.

When the option is unselected, the simulation shows all rapid moves from point A to point B as straight lines

Supported axes — Select the axes that are supported.

- Select either 2-axis only or Multi axis.

- If you select

Multi axis, select at least one option from:

- 3-axis

- 4-axis

- 5-axis positioning

- 5-axis simulation

- If you select

4-axis, select the indexing that the machine can perform:

- X-indexing

- Y-indexing

- Z-indexing

Macro Type — Select how macros are formatted when the part program requires them.

Select from:

- Local — This places macro definitions within the main NC part program.

- End of Program — This places macro definitions at the end of the main part program (for example, Heidenhain controls). The PROGRAM END program format should be specified for output at the end of the main program and the FILE END program format should be specified for output at the end of these macro definitions.

- Not Available — Select this option if macros are not available.

- Individual Files — This places macro definition in a separate file (for example, FANUC and GE MC 2000 controls). The name of each macro file consists of the assigned name that was specified in Post and the system-assigned macro number. The internal sub-program name is automatically added to the main program name as the external file name.

- One File — This places all macro definitions in one file. Post generates two files, the main part program and a file containing all macros. This option can output to Bridgeport controls via the EZ-Utils module, CNCCOMMUNICATION option (Heidenhain DNC utility).

The name of the macro file comprises the assigned name specified in Post, MA (representing the macro specification) and the .txt file extension. For example, samplema.txt (macro file) and sample.txt.

Call local macro after it is defined — Select this option to automatically execute a macro when it is defined. Some controls (such as the Heidenhain 370) automatically execute macros when they are defined. For these controls deselect Call local macro after it is defined so that the macro is not called twice. For other types of controls, leave this option selected.

Reuse local macro number — This affects the behavior of the <MACRO#> reserved word which can be used in the Open / Close / Call Macro formats. Deselect this option to increment the number every time you define a new macro, or select it to keep using the same number.

Include first canned cycle move in macro— This outputs the current position as the first location of a macro.If deselected, the first move is not in the macro, instead it is assumed that it is output on the canned cycle line.

To properly include the first move in a macro, you must enable this option and use the logical variable <CYCLE-MACRO> to suppress performing the canned cycle on the canned cycle line.

For a Fanuc 0M, if a canned cycle line ends with K0, the machine goes into canned cycle mode, but the actual canned cycle is not performed. Here is the drilling format for the Fanuc 0M.

{N<SEQ>}<CYCLE>{X<X-COORD>}{Y<Y-COORD>}

R<ABS-ZCLEAR>Z<ABS-DEPTH>F<FEED>

<IF><CYCLE-MACRO><THEN>

K0

<ENDIF>

<EOB>

Post supports local coordinates — Select this option for a post that redefines the coordinate system using datum shifts.

Post supports incremental macros — Select this option for a post that program milling macros incrementally.

Force segment start for each operation — Select from:

- Controlled by setting in the CAM software — Set this option in Post Options in FeatureCAM.

- ON — Select this option to force a Segment Start format for each operation.

- OFF — Select this option to disable forced Segment Start formats for each operation.

Sequence Max — Select this option to enter a maximum value for sequence numbers, after which sequence numbers restart. If Sequence Max is deselected, no limit is set.

NC File Extension — The default file extension for your CNC programs. For example if it is set to txt, and your part is called bracket, the G-code file is called bracket.txt.

Machine tool and post support cylindrical interpolation — Enable this option to support cylindrical interpolation in the NC code for Turn/Mill and 4th-axis wrapped parts, using G07. This makes the NC code shorter, and smaller in memory size, and gives better interpretation of cutter compensation.

Restrict angles to be between -360 and 360 — When selected, moves containing rotations greater than 360 degrees are split into smaller pieces.