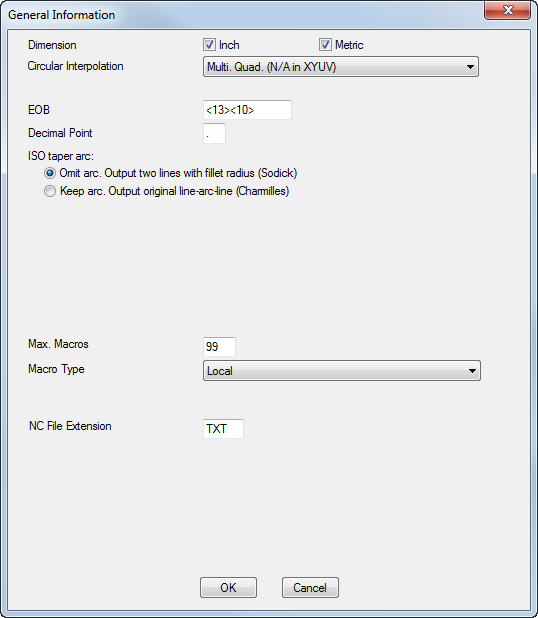

Allows you to specify the output program format. The General Information dialog is displayed.

You can edit parameters by selecting them, typing the value, or toggling them. If you enter a new value, press the Enter key. The comment block describes the post processor.

You can specify the following parameters:

Dimension — Selects whether the post is in Inch or Metric units, or both. We recommend posts that support both units.

Circular Interpolation — Select the programming format on the CNC for which the post processor is being built. You can choose Multi-Quadrant, Single Quadrant, or Not Supported option, as appropriate. For example, if the Numerical Control cannot drive an arc across a quadrant line (plus or minus X and Y axes), then select Single Quadrant circular interpolation. When circular interpolation is turned off in post, then wrap tolerance is used to control fineness of toolpath.

Decimal point — Enter the decimal point character, for example: (US and UK) or (Europe).

ISO Taper Arc — This controls the output of arcs for tapered corners in the ISO-style.

The options are:

- Omit arc - in this case, line of G-code for the arc is left out. Instead a modifier is added to the end of the linear move indicating that a fillet should be added. This is primarily used for Sodick machines.

- Keep arc - this is the normal case where G-code is output for the arc move.

Macro Type — Select how macros are formatted when the part program requires them.

Select from:

- Local — This places macro definitions within the main NC part program.

- End of Program — This places macro definitions at the end of the main part program (for example, Heidenhain controls). The PROGRAM END program format should be specified for output at the end of the main program and the FILE END program format should be specified for output at the end of these macro definitions.

- Not Available — Select this option if macros are not available.

- Individual Files — This places macro definition in a separate file (for example, FANUC and GE MC 2000 controls). The name of each macro file consists of the assigned name that was specified in Post and the system-assigned macro number. The internal sub-program name is automatically added to the main program name as the external file name.

- One File — This places all macro definitions in one file. Post generates two files, the main part program and a file containing all macros. This option can output to Bridgeport controls via the EZ-Utils module, CNCCOMMUNICATION option (Heidenhain DNC utility).

The name of the macro file comprises the assigned name specified in Post, MA (representing the macro specification) and the .txt file extension. For example, samplema.txt (macro file) and sample.txt.

NC File Extension — The default file extension for your CNC programs. For example if it is set to txt, and your part is called bracket, the G-code file is called bracket.txt.