You can use the Threading tab of the Turning Feature Properties dialog to edit the machining settings for a Thread feature.

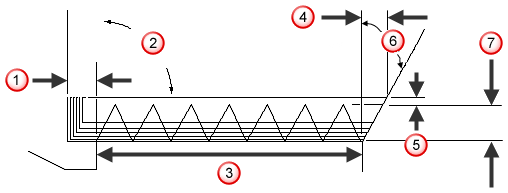

Some of the Threading attributes are shown on this diagram:

|

|

|

|

|

|

End clearance — Enter the distance that the tool feeds past the end of the thread (into the relief groove) before retracting from the part's surface.

Infeed angle — Enter an unsigned, incremental value from the positive Z axis.

Start clearance — This value is the position to which the tool traverses before engaging into the workpiece.

Start threads — If set to

1, a single thread is created. If set to

2 or

3, multiple start threads are created. The number of threads per inch (or per mm) for each thread is divided by the number of threads. For example, if you create a thread with 10 threads per inch with 2 start threads, then each thread is 5 threads per inch 180 apart.

apart.

Tool change location is the point where the tip of the tool moves before a tool change.

End clearance

End clearance

Withdraw angle

Withdraw angle

Depth

Depth

Start clearance

Start clearance

Clearance

Clearance

Infeed angle

Infeed angle

Height

Height