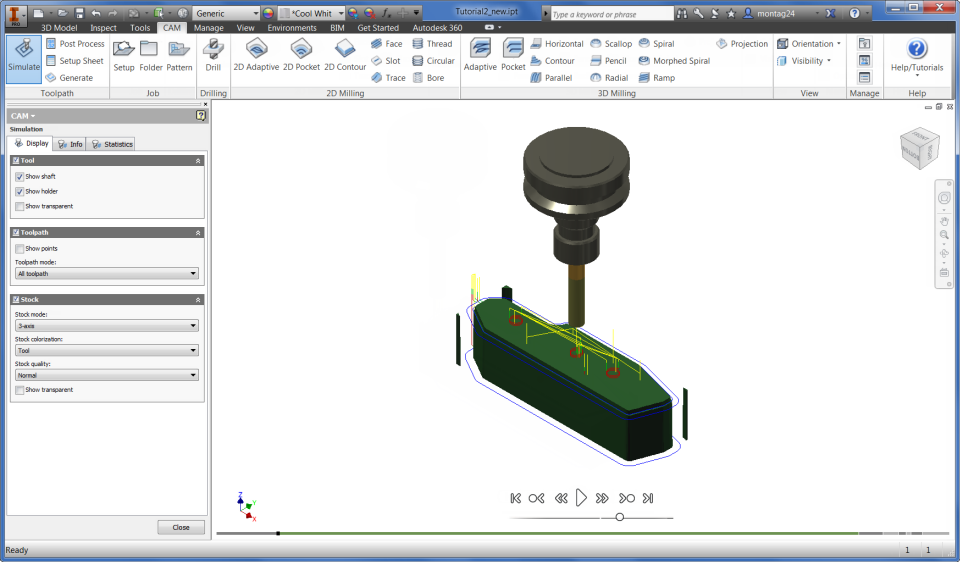

Simulation

After generating a toolpath, you can inspect the result with the integrated Simulate tool. Using the Play feature, the movement of the tool is simulated. The many controls include simulation speed and direction, visibility of tool, shaft and tool holder as well as the coloring of rapid moves, lead moves, and cutting moves.

The features on the Simulate Info and Statistics tabs allow you to measure distances or dynamically view all the vital information about tools, feed/speed, estimated machining time, etc. Full 3+2 machining is supported, and multiple toolpaths can be inspected in a single operation.

Stock Simulation

The integrated Stock Simulation allows you to see the actual stock being removed from a solid block of material, and to automatically check for shaft and clamp/fixture collisions. The resulting solid model can be inspected by coloring the surface according to the tool that cuts each part of the surface.

Post Processing

No CAM system is complete without a post processor to convert the generated toolpath into a format understood by the CNC machine control. Inventor HSM uses a flexible and fast post processor based on the JavaScript programming language to perform this critical task. Inventor HSM comes with numerous generic post processor configurations, with each post processor customizable to your specific requirements.

Generic post processors include Fanuc, Heidenhain, Haas, Hurco, Mazak, MillPlus, Okuma, Siemens, Yasnak, and many more.

Autodesk HSM Edit

Inventor HSM includes Autodesk HSM Edit for inspecting and manually editing NC program files. Autodesk HSM Edit provides a number of CNC code specific functions including line numbering/renumbering, XYZ range finder, and file compare. It also features a DNC link for reliable RS-232 communications with a variety of CNC controls.