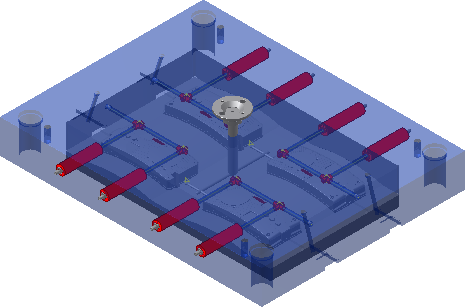

Checks cooling channels for safety, interference, and distance between cooling system segments.

- Access

- On the Mold Layout tab, click Cooling Channel Check

.

.

Settings

- Safety Check

- Checks the distance between the selected cooling segments and components for safety violations.

- Interference Check

- Checks the distance between the selected cooling segments and components (such as pins, screws, and guides) for interference violations.

- Cooling System Check

- Checks the distance between the selected cooling segments for minimum distance violations.

- Minimum Distance

- Specifies the minimum clearance distance.

Selection

- Selection Set #1

- Selects the cooling segments for checking. Click Select All to select all cooling segments.

- Selection Set # 2

- Selects the components for safety and interference checking. Select the cooling segments for cooling system checking. Click Select All to select all cooling segments.

- Use the Last Selection Set

- Reuses the previous selection sets. Use to recheck the cooling system after making changes to the model.

Quick Define Set # 2

- All Cores/Cavities

- Click to select all cores/cavities for a safety check.

- Mold Base Plates

- Click to select all mold base plates for a safety check.

- All Ejectors

- Click to select all ejectors for an interference check.

- Mold Base Components

- Click to select all mold base components for an interference check.

Cooling Errors Detected

Reports the quantity of errors detected.

- More

- Lists the items, parts, and error volume. Right-click and select Find in Window to zoom to the selected error in the graphics window.

- Additional Information

- Click

to copy the error list to the clipboard.

to copy the error list to the clipboard. Click

to print the error list.

to print the error list.