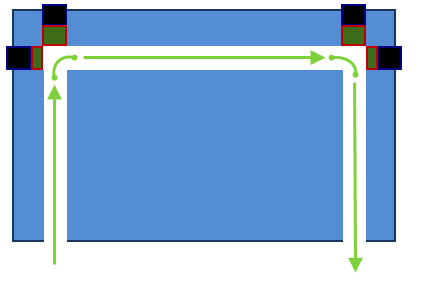

Set coolant outlets to define the cooling channel pathway.

Often the CAD drawings supplied for analysis are also used for the machining of the mold. In these cases, cooling channels are represented as holes that can pass all the way through the mold and intersect with other channels. When the mold is manufactured, the end of these holes are plugged forcing the coolant to flow around the channel.

When modeling this channel, instead of including the channel plugs, specify both the coolant inlet and outlet and the pathway is automatically determined.

It is preferable to maintain the representation of the dead ends of the coolant channels. Coolant stagnates in these areas and heats up with the molding process. The analysis takes this into consideration giving a more accurate result.