Changes have been made to the 3D Flow solver, including fiber orientation, to improve accuracy.

Mesh sensitivity around injection locations

Improvements have been made to the 3D Flow solver to reduce the mesh sensitivity for finer meshes around the injection location. The improvements reduce the occurrence of non-physical excessive shear heating when the gate is located at the corner.

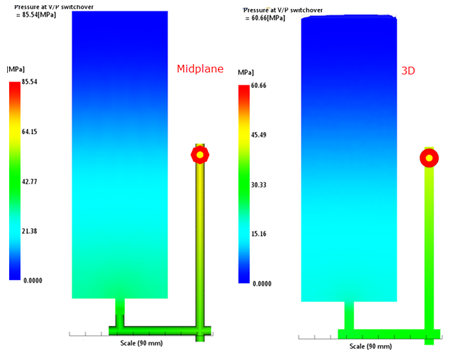

Specific heat calculation

The specific heat calculation for partially frozen tetrahedral mesh elements has been improved for materials with variable specific heat. This change also improves the accuracy of the 3D Flow pressure drop prediction.

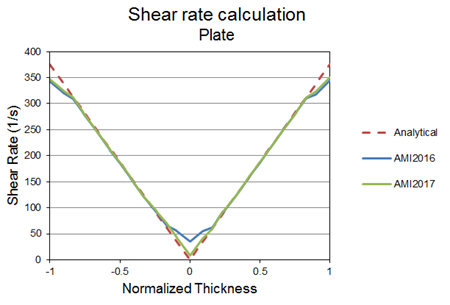

Shear rate calculation

The shear rate calculation in tetrahedral elements has been improved so that the true solution of zero at the part centerline is approached more rapidly as the mesh is refined. The modification slightly improves the shear rate dependent viscosity prediction and thus the flow accuracy. Note that this tends to increase pressure drops in some parts, especially if the tetrahedral mesh is coarse.

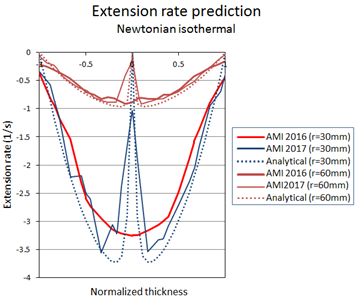

Extension rate prediction

3D Flow solver extension rate prediction is now closer to the analytical solution, for isothermal Newtonian and power-law fluids.