This example shows you how to find the hole intersections and reduce the feed rate and spindle speed at these intersections.

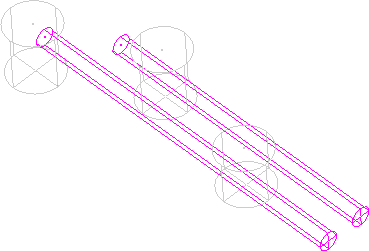

Starting with a model containing two feature sets, one containing three holes (grey), the other containing two holes (magenta).

- From the Hole Feature Sets context menu, select Find hole intersections. This creates intersections wherever the two sets of holes intersect fully or partially.

- Create a block and drill tool.

- Display the Single Peck Drilling dialog.

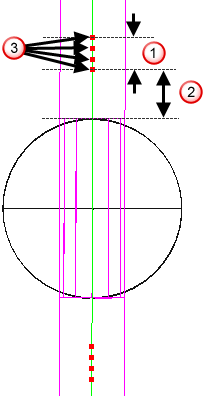

- Select the Feed rate reduction page:

- Select Hole intersections.

- Enter a Safety margin of 30 in the Hole intersections area.

- Enter a Distance of 20 in the Hole intersections area.

- Enter a Feed rate of 40 in the Hole intersections area.

- Enter a Spindle speed of 20 in the Hole intersections area.

- Enter a Number of steps of 3.

- Enter a Dwell time of 1.

- Click Calculate.

This creates a drilling toolpath which slows down at the hole intersections.

- Click Toolpath tab > Draw > Display > Points to show each step.

Distance

Distance Safety margin

Safety margin Steps

Steps