Use Trim/Extend, Quick Connect, or Route and Fill to fill gaps in a fabrication model for ductwork, pipework, or electrical containment.

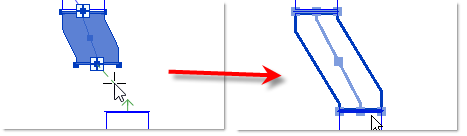

- Use the Trim/Extend tool to fill a gap between two straights, for example, when connecting a duct branch to a main or pipework to a header.

- Use the Quick Connect tool to fill a gap between a fitting and another straight where no additional fittings are needed. The Quick Connect command is available only when a fitting is selected. The command is disabled when a straight is selected.

- Use the Route and Fill tool to add parts between two open connectors in a faster, more efficient way than placing parts one by one. The Route and Fill tool provides one or more solutions depending on the service. You can narrow the number of solutions by filtering the fittings used.

Note: A route must exist in a single plane. Solutions that require two planes or three bends are not supported.

Video: Filling Gaps in a Fabrication Model in Revit

With any of these auto fill tools (Trim/Extend, Quick Connect, or Route and Fill), you can specify certain parts to be excluded. For more information, see Exclude Fabrication Parts from Auto Fill Tools.

To fill a gap between two straights, use the Trim/Extend tool. See Trim and Extend Elements.

To use the Quick Connect tool, follow these steps:

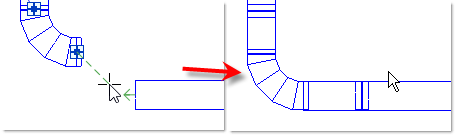

- Select a fabrication fitting with an open connector.

- Right-click and click Quick Connect or simply drag from the starting connector.

- Click an open connector on another fabrication part to establish the end of the route.

Quick connect is useful for stretching an offset or taper, or dragging a bend.

If more than one solution is available, Revit provides the option to open the Route and Fill editor.

To use the Route and Fill tool, follow these steps:

- Select a fabrication part with an open connector. If the selected part has more than one open connector, you must select the connector you want to route from.

- Click Modify | Fabrication Parts tab

Edit panel

Edit panel

(Route and Fill).

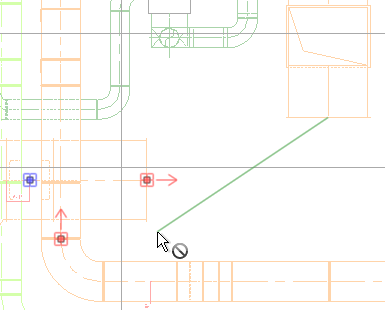

As you move the mouse, Revit surveys the open connectors in the view that are on the same plane to determine if a connection is possible. An arrow displays on each available connector.Note: A route must exist in a single plane. Solutions that require two planes or three bends are not supported.Note: The connection angle cannot be greater than 90 degrees.Tip: You can change the color of the arrow on the available connectors in the Fabrication Settings dialog.

(Route and Fill).

As you move the mouse, Revit surveys the open connectors in the view that are on the same plane to determine if a connection is possible. An arrow displays on each available connector.Note: A route must exist in a single plane. Solutions that require two planes or three bends are not supported.Note: The connection angle cannot be greater than 90 degrees.Tip: You can change the color of the arrow on the available connectors in the Fabrication Settings dialog.

- Click an open connector to establish the end of the route.

The start point must be a connector on a fabrication part. However, the end point may be on a generic Revit element such as a duct, pipe, or mechanical equipment.

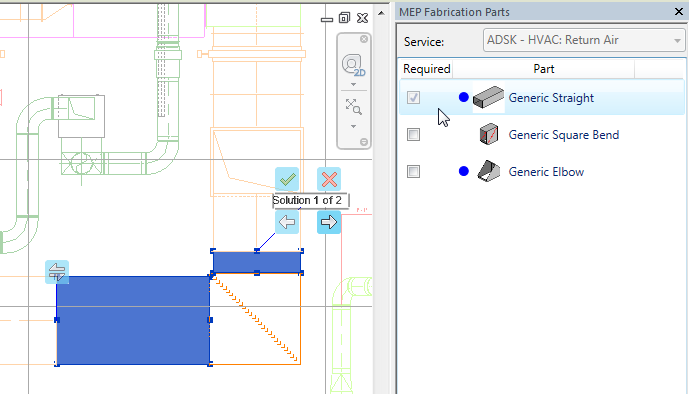

- Click Previous and Next on the Solutions panel or

and

and

in the drawing area to view the possible solutions. Solutions requiring the fewest number of parts display first. As you click Next, the solutions displayed require more parts to complete the run.

Tip: You can also press the right and left arrows keys to view the next and previous solutions.

in the drawing area to view the possible solutions. Solutions requiring the fewest number of parts display first. As you click Next, the solutions displayed require more parts to complete the run.

Tip: You can also press the right and left arrows keys to view the next and previous solutions.The MEP Fabrication Parts palette displays all the parts used in the available solutions. A blue dot indicates that a part is used in the currently selected solution. As you position the cursor on a part in the list, the part is highlighted in the drawing area. In the MEP Fabrication Parts palette, select the check boxes to filter the list of available fittings and limit the number of solutions.

- (Optional) Changes in size, shape, and direction occur from the starting point of the route. To reverse the start and end points of the route, in the drawing area, click

(Start Route from Opposite End).

(Start Route from Opposite End).

- (Optional) To route to a tee or tap solution and select the centerline as the second point on a straight segment instead of an open connector, on the Solutions panel, click

(Cut Into). Smart Snapping is automatically disabled when Cut Into is enabled.

(Cut Into). Smart Snapping is automatically disabled when Cut Into is enabled.

- Click Finish on the Solutions panel or

in the drawing area to accept a solution and complete the run.

Note: You can also press Enter to finish the command.

in the drawing area to accept a solution and complete the run.

Note: You can also press Enter to finish the command.