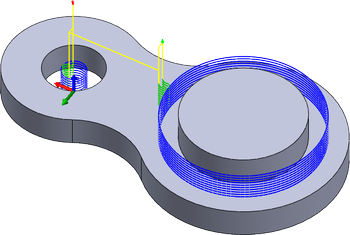

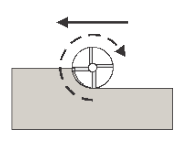

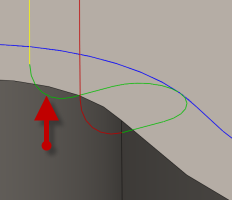

Circular is used for milling cylindrical holes and bosses. You can only select Circular Faces for this toolpath. Heights and depths are determined from the selected Face. Circular will ramp on and ramp off for each pass around the profile. It does not stay in contact like the Bore Toolpath.

|

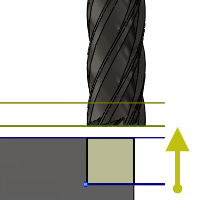

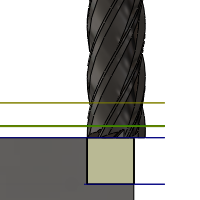

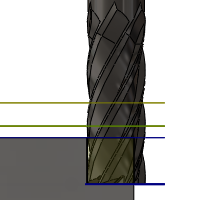

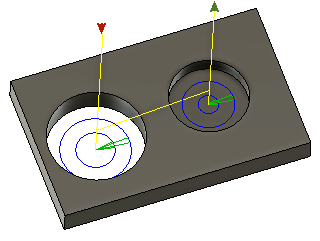

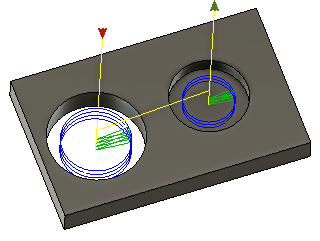

Shown with Multi-Passes and Multi-Depth cuts. |

|

Access: |

Ribbon:

CAM tab

2D Milling panel

2D Milling panel

Circular

Circular

|

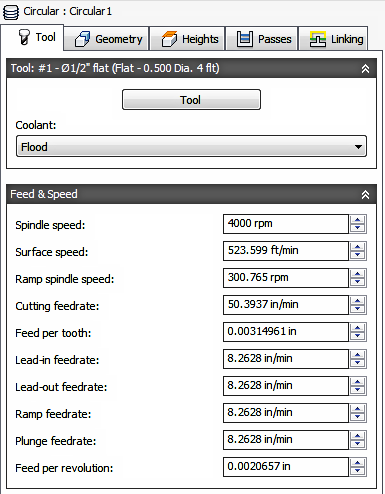

Tool tab settings

Tool tab settings

Coolant

Select the type of coolant used with the machine tool. Not all types will work with all machine postprocessors.

Feed & Speed

Spindle and Feedrate cutting parameters.

- Spindle Speed - The rotational speed of the spindle expressed in Rotations Per Minute (RPM)

- Surface Speed - The speed which the material moves past the cutting edge of the tool (SFM or m/min)

- Ramp Spindle Speed - The rotational speed of the spindle when performing ramp movements

- Cutting Feedrate - Feedrate used in regular cutting moves. Expressed as Inches/Min (IPM) or MM/Min

- Feed per Tooth - The cutting feedrate expressed as the feed per tooth (FPT)

- Lead-In Feedrate - Feed used when leading in to a cutting move.

- Lead-Out Feedrate - Feed used when leading out from a cutting move

- Ramp Feedrate - Feed used when doing helical ramps into stock

- Plunge Feedrate - Feed used when plunging into stock

- Feed per Revolution - The plunge feedrate expressed as the feed per revolution

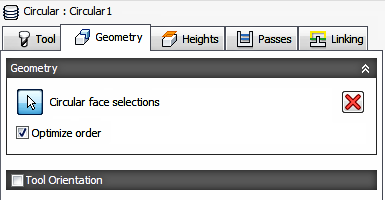

Geometry tab settings

Geometry tab settings

Geometry

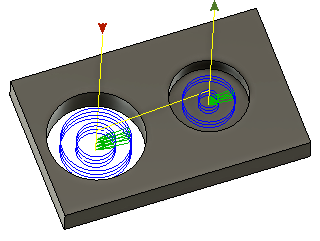

Select any cylindrical holes, pockets or bosses. Only Face selections are allowed.

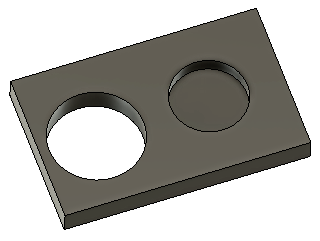

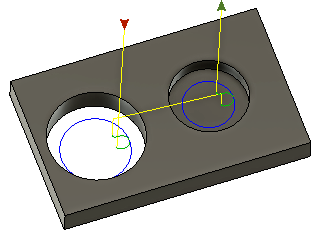

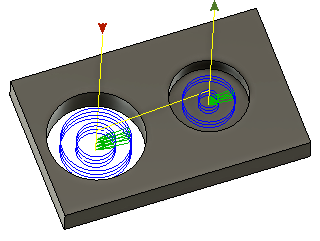

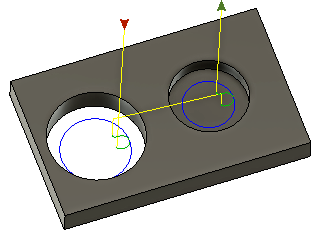

Part with no selections. |

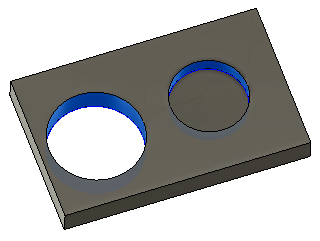

Hole Face and circular pocket Face selection. |

Optimize Order

Enable to order the selected Faces for the shortest distance between cuts

Tool Orientation

Specifies how the tool orientation is determined using a combination of triad orientation and origin options.

The Orientation drop-down menu provides the following options to set the orientation of the X, Y, and Z triad axes:

- Setup WCS orientation - Uses the workpiece coordinate system (WCS) of the current setup for the tool orientation.

- Model orientation - Uses the coordinate system (WCS) of the current part for the tool orientation.

- Select Z axis/plane & X axis - Select a face or an edge to define the Z axis and another face or edge to define the X axis. Both the Z and X axes can be flipped 180 degrees.

- Select Z axis/plane & Y axis - Select a face or an edge to define the Z axis and another face or edge to define the Y axis. Both the Z and Y axes can be flipped 180 degrees.

- Select X & Y axes - Select a face or an edge to define the X axis and another face or edge to define the Y axis. Both the X and Y axes can be flipped 180 degrees.

- Select coordinate system - Sets a specific tool orientation for this operation from an Inventor User Coordinate System (UCS) in the model. This uses both the origin and orientation of the existing coordinate system. Use this if your model does not contain a suitable point & plane for your operation.

The Origin drop-down menu offers the following options for locating the triad origin:

- Setup WCS origin - Uses the workpiece coordinate system (WCS) origin of the current setup for the tool origin.

- Model origin - Uses the coordinate system (WCS) origin of the current part for the tool origin.

- Selected point - Select a vertex or an edge for the triad origin.

- Stock box point - Select a point on the stock bounding box for the triad origin.

- Model box point - Select a point on the model bounding box for the triad origin.

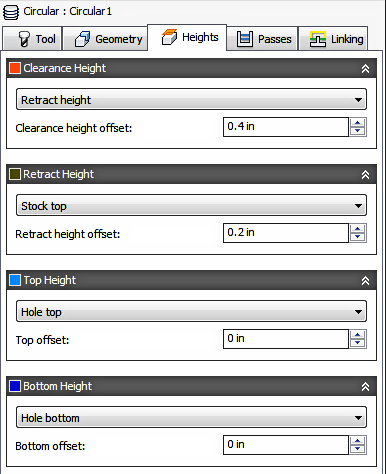

Heights tab settings

Heights tab settings

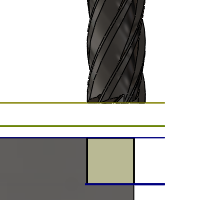

Clearance Height

The Clearance height is the first height the tool rapids to on its way to the start of the tool path.

Clearance Height

- Retract height: incremental offset from the Retract Height.

- Top height: incremental offset from the Top Height.

- Bottom height: incremental offset from the Bottom Height.

- Model top: incremental offset from the Model Top.

- Model bottom: incremental offset from the Model Bottom.

- Stock top: incremental offset from the Stock Top.

- Stock bottom: incremental offset from the Stock Bottom.

- Hole top: incremental offset from the Hole Top.

- Hole bottom: incremental offset from the Hole Bottom.

- Selection: incremental offset from a Point (vertex), Edge or Face selected on the model.

- Origin (absolute): absolute offset from the Origin that is defined in either the Setup or in Tool Orientation within the specific operation.

Clearance height offset:

The Clearance height offset is applied and is relative to the Clearance height selection in the above drop-down list.

Retract Height

Retract height sets the height that the tool moves up to before the next cutting pass. Retract height should be set above the Feed height and Top. Retract height is used together with the subsequent offset to establish the height.

Retract Height

- Clearance height: incremental offset from the Clearance Height.

- Top height: incremental offset from the Top Height.

- Bottom height: incremental offset from the Bottom Height.

- Model top: incremental offset from the Model Top.

- Model bottom: incremental offset from the Model Bottom.

- Stock top: incremental offset from the Stock Top.

- Stock bottom: incremental offset from the Stock Bottom.

- Hole top: incremental offset from the Hole Top.

- Hole bottom: incremental offset from the Hole Bottom.

- Selection: incremental offset from a Point (vertex), Edge or Face selected on the model.

- Origin (absolute): absolute offset from the Origin that is defined in either the Setup or in Tool Orientation within the specific operation.

Retract height offset:

Retract height offset is applied and is relative to the Retract height selection in the above drop-down list.

Top Height

Top height sets the height that describes the top of the cut. Top height should be set above the Bottom. Top height is used together with the subsequent offset to establish the height.

Top Height

- Clearance height: incremental offset from the Clearance Height.

- Retract height: incremental offset from the Retract Height.

- Bottom height: incremental offset from the Bottom Height.

- Model top: incremental offset from the Model Top.

- Model bottom: incremental offset from the Model Bottom.

- Stock top: incremental offset from the Stock Top.

- Stock bottom: incremental offset from the Stock Bottom.

- Hole top: incremental offset from the Hole Top.

- Hole bottom: incremental offset from the Hole Bottom.

- Selection: incremental offset from a Point (vertex), Edge or Face selected on the model.

- Origin (absolute): absolute offset from the Origin that is defined in either the Setup or in Tool Orientation within the specific operation.

Top offset:

Top offset is applied and is relative to the Top height selection in the above drop-down list.

Bottom Height

Bottom height determines the final machining height/depth and the lowest depth that the tool descends into the stock. Bottom height needs to be set below the Top. Bottom height is used together with the subsequent offset to establish the height.

Bottom Height

- Clearance height: incremental offset from the Clearance Height.

- Retract height: incremental offset from the Retract Height.

- Top height: incremental offset from the Top Height.

- Model top: incremental offset from the Model Top.

- Model bottom: incremental offset from the Model Bottom.

- Stock top: incremental offset from the Stock Top.

- Stock bottom: incremental offset from the Stock Bottom.

- Hole top: incremental offset from the Hole Top.

- Hole bottom: incremental offset from the Hole Bottom.

- Selection: incremental offset from a Point (vertex), Edge or Face selected on the model.

- Origin (absolute): absolute offset from the Origin that is defined in either the Setup or in Tool Orientation within the specific operation.

Bottom offset:

Bottom offset is applied and is relative to the Bottom height selection in the above drop-down list.

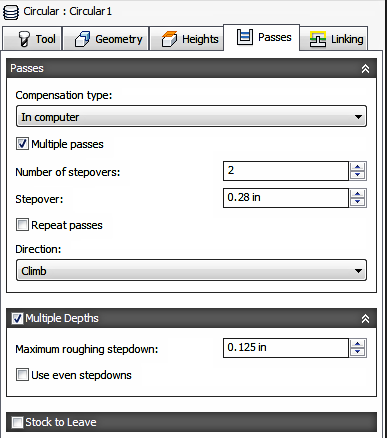

Passes tab settings

Passes tab settings

Compensation type:

Specifies the compensation type.

- In computer - Tool compensation is calculated automatically by Autodesk HSM based on the selected tool diameter. The post processed output contains the compensated path directly, instead of G41/G42 codes.

- In control - Tool compensation is not calculated, but rather G41/G42 codes are output to allow the operator to set the compensation amount and wear on the machine tool control.

- Wear - Works as if In computer was selected, but also outputs the G41/G42 codes. This lets the machine tool operator adjust for tool wear at the machine tool control by entering the difference in tool size as a negative number.

- Inverse wear - Identical to the Wear option, except that the wear adjustment is entered as a positive number.

Multiple Passes

Enable to make multiple cuts in the XY plane.

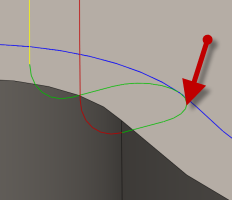

Shown with a single pass and Lead to Center disabled. |

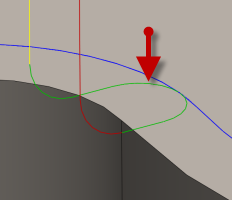

Shown with 2 passes of .280 in. and Lead to Center enabled. |

Number of stepovers:

The number of roughing steps.

Stepover

Specifies XY stepover distance between passes. By default, this value is 95% of the cutter diameter less the tool corner radius.

XY Stepover

Repeat passes

Enable to perform the final finishing pass twice to remove stock left due to tool deflection.

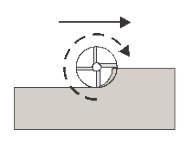

Direction

This setting determines the side of the toolpath from which the tool center is offset. Choose between Climb milling sideways compensation or Conventional milling sideways compensation.

Left (climb milling)

Climb Milling |

Right (conventional milling) Conventional Milling |

Multiple Depths

Enable to take multiple depth cuts in Z.

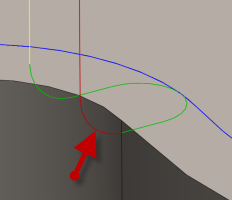

Shown with a Depth of .125 and Lead to Center enabled. |

Shown with Multi-Passes and Multi-Depth cuts . Lead to Center enabled. |

Maximum roughing stepdown:

Specifies the maximum stepdown between Z-levels for roughing.

Maximum stepdown - shown without finishing stepdowns

Use even stepdowns

Enable to create equal distances between machining passes.

Example: Suppose you are machining a profile with a depth of 23 mm and a maximum stepdown = 10 mm.

- With Use even stepdowns enabled - you get three passes with the first value at -7.666 mm, the second at 15.3333 mm, and the third at -23 mm.

- With Use even stepdowns disabled - again you get three passes, the first at -10 mm, the second at -20 mm, and the third at -23 mm.

Stock to Leave

Positive Positive Stock to Leave - The amount of stock left after an operation to be removed by subsequent roughing or finishing operations. For roughing operations, the default is to leave a small amount of material. |

None No Stock to Leave - Remove all excess material up to the selected geometry. |

Negative Negative Stock to Leave - Removes material beyond the part surface or boundary. This technique is often used in Electrode Machining to allow for a spark gap, or to meet tolerance requirements of a part. |

Negative Stock to Leave - Removes material beyond the part surface or boundary. This technique is often used in Electrode Machining to allow for a spark gap, or to meet tolerance requirements of a part.

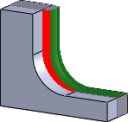

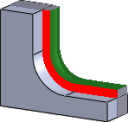

Radial (wall) stock to leave

The Radial stock to leave parameter controls the amount of material to leave in the radial (perpendicular to the tool axis) direction, i.e. at the side of the tool.

Radial stock to leave |

Radial and axial stock to leave |

Specifying a positive radial stock to leave results in material being left on the vertical walls and steep areas of the part.

For surfaces that are not exactly vertical, Autodesk HSM interpolates between the axial (floor) and radial stock to leave values, so the stock left in the radial direction on these surfaces might be different from the specified value, depending on surface slope and the axial stock to leave value.

Changing the radial stock to leave automatically sets the axial stock to leave to the same amount, unless you manually enter the axial stock to leave.

For finishing operations, the default value is 0 mm / 0 in, i.e. no material is left.

For roughing operations, the default is to leave a small amount of material that can then be removed later by one or more finishing operations.

Negative stock to leave

When using a negative stock to leave, the machining operation removes more material from your stock than your model shape. This can be used to machine electrodes with a spark gap, where the size of the spark gap is equal to the negative stock to leave.

Both the radial and axial stock to leave can be negative numbers. However, the negative radial stock to leave must be less than the tool radius.

When using a ball or radius cutter with a negative radial stock to leave that is greater than the corner radius, the negative axial stock to leave must be less than or equal to the corner radius.

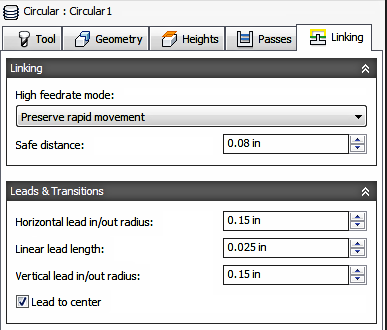

Linking tab settings

Linking tab settings

High feedrate mode:

Specifies when rapid movements should be output as true rapids (G0) and when they should be output as high feedrate movements (G1).

- Preserve rapid movement - All rapid movements are preserved.

- Preserve axial and radial rapid movement - Rapid movements moving only horizontally (radial) or vertically (axial) are output as true rapids.

- Preserve axial rapid movement - Only rapid movements moving vertically.

- Preserve radial rapid movement - Only rapid movements moving horizontally.

- Preserve single axis rapid movement - Only rapid movements moving in one axis (X, Y or Z).

- Always use high feed - Outputs rapid movements as (high feed moves) G01 moves instead of rapid movements (G0).

This parameter is usually set to avoid collisions at rapids on machines which perform "dog-leg" movements at rapid.

High feedrate:

The feedrate to use for rapids movements output as G1 instead of G0.

Safe distance:

Minimum distance between the tool and the part surfaces during retract moves. The distance is measured after stock to leave has been applied, so if a negative stock to leave is used, special care should be taken to ensure that safe distance is large enough to prevent any collisions.

Horizontal lead-in radius:

Specifies the radius for horizontal lead-in moves.

Horizontal lead-in radius

Horizontal lead-out radius:

Specifies the radius for horizontal lead-out moves.

Horizontal lead-out radius

Linear lead length:

Specifies the length of the linear leads.

Vertical lead-in radius:

The radius of the vertical arc smoothing the entry move as it goes from the entry move to the toolpath itself.

Vertical lead-in radius

Vertical lead-out radius:

Specifies the radius of the vertical lead-out.

Vertical lead-out radius

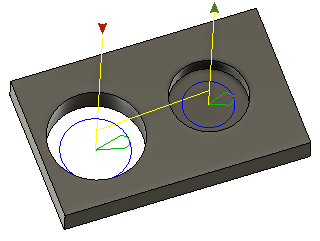

Lead To Center

When enabled the lead in/out movement will start from the center of the hole or pocket.

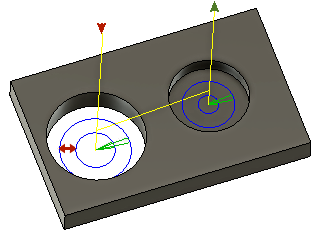

Lead to Center disabled. |

Lead to Center enabled. |