All pump manufacturers ship their products with a unique pump curve. This data can be used to improve the accuracy of the simulation.

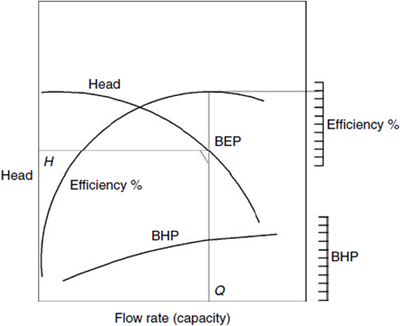

The generic performance curve shown in figure 1 represents the pressure rise flow rate relationship through a pump. The coolant flow solver calculates a flow resistance curve for all the pressure loss elements specified in the entire circuit. This flow resistance is connected to the pump curve, and where it intersects the pump curve is the operating point of the pump. This defines the efficiency at which the pump is operating. If you model the circuit and pipe work to the inlet and exit of the pump, in exact detail, then the solution from the solver at the inlet node predicts the precise suction head at the entrance to the pump. This pressure can be used to check whether the installation allows for sufficient net positive suction head (NPSH). This is a very important parameter when designing pump installations.

Figure 1. Generic performance curve for a centrifugal pump. (Image from Menon, E. Shashi. (2005), Piping calculations Manual, McGraw-Hill, Inc.)

Pump installations in cooling circuits are very sensitive to the precise flow conditions in the circuit, and need to be selected very carefully. When selecting pumps for your circuit, first perform the coolant flow simulation using conventional pressure and flow rate boundary conditions at the pump installation point. Once you know the desired flow rate and pressure at the pump installation point in the circuit, then choose a pump that provides this pressure at this flow rate, at the pump's optimum efficiency. Then enter the pump curve data for that pump into the solver and run the simulation again. All the other "what if" scenarios involving the pump can be evaluated from there. Pump selection is very specific to the circuit design, and generic solutions to pump selection do not exist.

To use the data from your pump curve, in place of the default generic pump curve, enter at least 4 matching head vs flow rate points. You also need the reference density of the fluid, in order to link the element to the rest of the network.