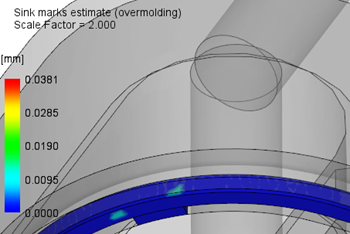

The Sink marks (overmolding) results display simulated sink marks on the overmolded component.

To generate these result, import a

3D model that includes an overmolding component, select

Thermoplastics Overmolding as the molding process, and choose an analysis sequence that includes

Overmolding Pack.

3D model that includes an overmolding component, select

Thermoplastics Overmolding as the molding process, and choose an analysis sequence that includes

Overmolding Pack.

The Sink marks estimate (overmolding) result displays the calculated depths of sink marks in the overmolded component, and displays a legend to detail the depth differences.

The Sink marks shaded (overmolding) result displays the sink marks in the part as lines and marks more indicative of the actual appearance.

These results indicate the presence and location of sink marks, and voids, likely to be caused by features on the opposite face of the surface. Sink marks typically occur in moldings with thicker sections, or at locations opposite ribs, bosses or internal fillets. The result does not indicate sink marks caused by locally thick regions.

Using these results

As sink marks are a visual rather than a structural defect, evaluate the result against the visual design specifications of the overmolded component. Lighter colors and textured surfaces tend to make sink marks less visible.

The result index indicates the degree of severity of depth, as affected by the material, part geometry, position relative to the injection location, and mold filling conditions. Change any of these variables to determine its contribution to the sink mark's severity.

Generally, if the thickness of the rib is less than, or equal to, 60% of the main wall section, then there are likely to be no significant sink marks.

If it is not possible to remove or reduce a sink mark, you can conceal it. This can be done by adding a design feature, such as a series of serrations on the area where it occurs.

Sink marks estimate (overmolding) result.

Things to look for

-

Alter the design to avoid thick sections and to reduce the thickness of any feature that intersects with the main surface.

-

Relocate the gate to, or near, the problem areas. This allows these sections to be packed before the thinner sections between the gate, and before the problem areas freeze.

-

Increase the size of gates and runners to delay the gate freeze-off time. This allows more material to be packed into the cavity.

-

Sometimes, decreasing the melt and mold temperature may be sufficient. Alternatively, use a less viscous melt.