This preconditioning data dialog is used to specify the data used to calculate the temperature of the molten plastic, or melt, as it starts to flow into the cavity for a reactive compression molding process.

To access this dialog ensure that you have selected reactive compression molding. Click

(), then click

Edit Data in the

Preconditioning analysis section of the dialog.

(), then click

Edit Data in the

Preconditioning analysis section of the dialog.

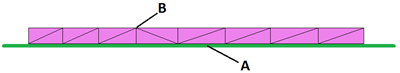

Figure 1: Example showing the bottom side of the resin, (A), in contact with the mold, and the top side of the resin, (B), in contact with air.

Dialog elements

| Dialog widget | Explanation |

|---|---|

| Delay time (compression molding) |

This is the time between when the resin, or initial charge, is placed on the mold and the time when the molding starts, and the mold touches the resin. |

| Heat transfer coefficient for preconditioning analysis (mold) |

Enter the HTC value to be used between the bottom of the part and the mold. For the side in contact with the mold (side A in Figure 1), the temperature of the mold is used as the external temperature for the heat transfer between the resin and the mold. |

| Heat transfer coefficient for preconditioning analysis (air) |

Enter the HTC value to be used between the top of the part and the air. For the side in contact with the air (side B in Figure 1), the temperature of the atmosphere is used as the external temperature for the heat transfer between the resin and the mold. |