This panel is used to define and create a finite-element mesh.

To access this panel, click

().

().

Tools tab

| Dialog element | Explanation |

|---|---|

| Remesh already meshed parts of the model | If this option is selected and you click

Mesh Now, all visible sections of the model will be remeshed.

If this option is deselected and you click Mesh Now, only those sections of the model that are visible and have not been meshed already, will be meshed. Note: Remeshing a runner section or cooling channel at a different edge length is done via the

Curves tab.

|

| Place mesh in active layer | Places the mesh layer in an active Layer pane after creation. |

| Mesh Now | Initiates the mesh generation task immediately, either in the Cloud or on the local machine, depending upon your selection. |

| Preview | Shows the effects of the settings on the meshing process. Edge nodes that will be generated using the set values are shown. This allows the mesh density to be reviewed before you proceed with generating the mesh. |

| Save Default Values | Saves all items marked with an asterisk as default. To alter the default values used, enter the required values and click

Save Default Values

Tip: This option is at the bottom of the panel and might be obscured by the Layer panel.

|

| Use Default Values | Restore the Default values.

Tip: This option is at the bottom of the panel and might be obscured by the Layer panel.

|

General tab

Determines what size elements will be created when the part is meshed, that is, the global mesh density.

| Dialog element | Explanation |

|---|---|

| Global edge length on surface | Enter a value to set the target mesh element length that will be used when generating the mesh.

Note: Your edge length setting may be ignored in certain areas of your mesh if the setting is not appropriate. For example, if you specify a long edge length, your target edge length will be used in straight areas of the mesh, but a shorter edge length may be used in curved areas.

|

| Match mesh | Allows you to align the mesh elements on the two corresponding surfaces of a Dual Domain mesh. |

| Stop after surface mesh generation | When meshing a model in 3D, this option allows the surface mesh to be investigated before proceeding with the meshing of the volume of the part. Critical areas of the part can be reviewed to ensure an appropriate mesh density. |

| Calculate thickness for Dual Domain meshes (Dual Domain and 3D meshes only) | When meshing a model with the Dual Domain technology, this option allows for the thickness of the mesh to also be calculated. |

| Apply extra refinement near gates (Dual Domain and 3D meshes only) | A finer mesh surrounding the gate will better capture the heat transfer, high shear rates and other critical properties that can rapidly change in this region. This option will refine the mesh around the gate and also any beam elements that are connected to the part. This is on by default. |

| Source geometry type (Midplane mesh only) | Specifies the type of geometry that is to be meshed.

Note: This option is only available if your part contains NURBS surfaces.

In the Study Tasks pane, after specifying a Midplane mesh, there are two possible tasks that the mesher can perform:

The following settings are available:

|

Curves tab

Curves are used to model the pathway of the feed system or cooling channels. Connected straight beam elements then follow this pathway. Factors such as the diameter, type of pathway (feed or channel) and bends within the path can affect the edge length prescribed to a beam element.

| Dialog element | Explanation |

|---|---|

| Use global edge length | Allows you to use the global edge length defined in the General tab for the beams on your curves as well. Alternatively, define a length to diameter ratio. |

| Ratio of Edge length to diameter for Feed system | A default value of 0.75 for the ratio of edge length to feed system diameter is used for beams with the assigned property of Runner. The larger this ratio, the longer the feed system elements will be. To prevent unrealistic values being used, the ratio used must be between 0.1 and 4.0.

Note: As the feed system is usually more critical to an analysis than the cooling system, the default edge length for a Runner beam is shorter than a Cooling circuit.

|

| Ratio of Edge length to diameter for Circuits | The ratio of edge length to cooling circuit diameter is used for beams with a property of

Circuits. Values for this ratio must fall between 0.5 and 8.0 with the default value of 2.5

Note: As the cooling circuit is usually less critical to an analysis than the feed system, the default edge length for a Circuit element is longer than a feed system beam element.

|

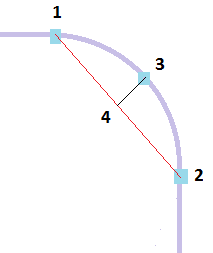

| Ratio of maximum chord height to chord length | Straight beams are used to emulate a curve that turns, for example, through 90 degrees. Applying an edge length that is suitable for the straight sections of a feed system, could result in an inaccurate representation of the curve.

To ensure an appropriate edge length is applied, the cord height (distance 3 to 4 in the following diagram) is divided by the chord length (distance 1 to 2). The default value for this ratio is 0.05 with an available range of 0.02 to 0.3. Shortening the edge length will reduce the chord height and so reduce this ratio.

The edge length for the beams in that section of the curve is calculated so that the resulting ratio falls into the allowable range. |

| Minimum number of elements on each curve for gates | Material entering the cavity is a critical phase of the injection molding simulation. It is recommended that the sections of the curve that represents the gates should be modeled with at least 3 beam elements. This is the default value for this parameter which can be adjusted in integer steps between 1 and 5. |

| Minimum number of elements on each curve for baffles and bubblers |

This value corresponds to the minimum number of beams elements that need to be created on the sections of the curve that represents the baffles and bubblers. 3 beam elements is the default and minimum value, and can be adjusted in integer steps between 3 and 50.

|

CAD tab

Allows you to set mesh parameters for CAD entities.

| Dialog element | Explanation |

|---|---|

| Use auto sizing | Check this option to automatically set the edge length and chord angle based on the dimensions and curvature.

Note: The global edge length defined in the

General Tab do not apply when this option is checked.

|

| Scale factor | Allows you to adjust the size of the mesh elements generated with the Use auto sizing by applying a scale factor. |

| Use global parameters | Check this option to use the global edge length defined in the General Tab. |

| Chord Angle | When selected, you can control the mesh density of curved features of the model by defining a chord angle. |

| Percentage of minimum curvature size vs. global size | Use this control to define the default minimum chord length in relation to the specified global edge length. The default is 20% of the global edge length.

Note: As you decrease the

Percentage of minimum curvature size relative to the

global size, you increase the number of mesh elements.

|

| Contact interfaces | There are three options that can be used for meshing assembly contact faces.

|

NURBS tab

Allows you to match a Dual Domain mesh or smooth a Midplane mesh to assist post-processing after analyzing the model.

| Dialog element | Explanation |

|---|---|

| NURBS surface mesher | Specifies which meshing technique should be used to generate the mesh on imported Non-uniform Rational B-Splines (NURBS) surfaces.

The following options are available:

|

| Enable chord height control | Increases the chance of creating a mesh that closely corresponds to curved surfaces.

Without chord height control, some surface curves, such as fillets, degrade when meshed. Chord height control is effective only with parts that have curved surfaces. Tip:

|

| Optimize aspect ratio by surface curvature control | Adjusts the size of the mesh to the local curvature on NURBS surfaces automatically. |

| Optimize aspect ratio by proximity control | Detects proximities between boundary curves automatically, and ensures adequate mesh refinement at locations where boundaries are close to one another. |

| Smooth mesh (NURBS surfaces only) | Allows you to smooth the edges of a Midplane mesh. |

| Merge tolerance | Sets the minimum distance between nodes that will be targeted when generating the mesh.

If adjacent nodes are closer together than this distance, these nodes will be merged together during mesh creation. |

Tetra tab

Sets the minimum number of elements that Autodesk Moldflow Insight uses to generate the 3D mesh.

| Dialog element | Explanation |

|---|---|

| 3D Mesher | Specifies which meshing technique should be used to generate the tetrahedral mesh.

The following options are available:

|

| Minimum number of elements through the thickness | Sets the minimum number of elements through the thickness that is targeted when generating a 3D mesh.

Tip: Increasing the number of elements through the thickness increases the total number of elements, which increases computation time. Despite increased computation time, it can be worthwhile to increase the minimum number of elements if you have a very thin part and you need an improved temperature solution. Check that the resultant Aspect Ratios are acceptable and decrease the

Global edge length on surface if necessary.

|