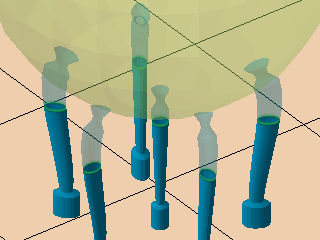

Bar supports connect two points, one on the part, and the other one either somewhere else on the same or a different part or on the platform. As such, bars only support single points. Bars may be created as volume-less single-path entities or solid voluminous ones. Bars may also be connected into bouquets that merge multiple bars into tree-like structures which terminate in single trunks at their bottom end.

| Bar contour | Notes | |

|---|---|---|

|

Bar contour |

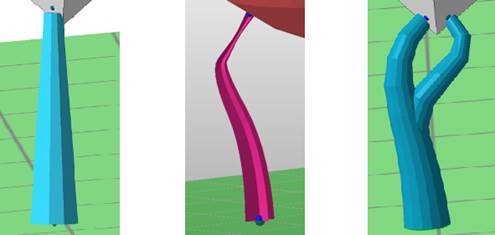

The type of structure.  From left: Straight bar with a solid contour; curved bar with right angle on the part, a cross-shaped cross section, and a breaking point; curved and solid bar with bouquet structure. |

Cross, Solid Bar, Solid Cross |

|

Polygon corner |

Determines the number of corners for the solid bar. The more corners, the more rounded the bar's cross section becomes. |

|

|

Angle at top |

When set beyond 0, a pointy end is added to the normally blunt end that terminates evenly in the part surface.

Note: This point will intrude into the part mesh, so you may want to also work with

Distance to part to reduce or avoid unwanted duplication of toolpath at the intersection.

|

0-60 ° |

|

Crosswidth |

Determines the thickness of the contours for the solid cross. |

0.01-20.00 mm |

|

Radial type |

Used to create solid bars with oval cross-sections. It aligns the oval cross section by the semi-major axis with the X or Y axis, or radially away from the supported object's outbox's center:

|

|

|

Radial factor |

Used to create solid bars with oval cross-sections. Makes the semi-major axis as long as the semi-minor axis times this factor. |

|

|

Distance to part |

Defines the distance between part and support. A negative value will make supports intrude into the part mesh. |

|

|

Width on part |

Determines the contour width for bar ends that terminate on a part surface. |

|

|

|

Determines the contour width for bar ends that terminate on a part surface at their lower end. |

This is optional. To disable defining a separate width for the lower end of a bar, set this to -1. |

|

Width on platform |

Determines the contour width for bar ends that terminate on the build platform surface. |

|

| Breaking point |

Generates a section where the bar narrows and expands to create a defined breaking point near the part surface, making it easier to remove supports from the part later on. |

Notes |

|

Breaking point |

Toggle yes or no to activate the breaking point. |

|

|

Breaking point width |

Defines the strength of the bar at the breaking point. It will be easier to remove the bar with a thinner breaking point. |

|

|

Width on end |

Making the part wider at the end of the breaking point can increase adhesion of the bar to the part. |

|

|

Breaking point height |

Determines the distance between the anchor point on the part and the kink on the breaking point. |

|

|

Height on start |

Determines the length over which the breaking point reduces to its center. |

|

|

Height on end |

Determines the length over which the breaking point expands back to the original width, or the width of the end on the part. |

|

|

Right angle on part |

Determines whether bars should make a small curve to terminate in a right angle at the supported surface, rather than terminating at whatever angle they would otherwise have. |

|

|

Distance to right angle |

Determines the distance away from the supported surface after which the bar starts to curve towards the other end. |

|

|

Smoothing distance |

Determines the length of sections that form the curve. The shorter the section, the finer the curve is resolved, resulting in a smoother transition but also increased triangle count. |

|

| Pad on platform |

A pad is a widened cross section at the platform end of a bar support to reinforce adhesion to the platform surface |

Notes |

|

Pad on platform |

Toggles pad creation. |

|

|

Pad width |

Determines the width of the created pad. |

|

|

Pad height |

Determines the height of the created pad. |

|

|

Use density map |

Applies information provided by a 3D heatmap to lighten or strengthen structures locally. |