Overview

When you enter the repair module, the context view displays 5 tabs:

- Status

- Actions

- Repair Scripts

- Shells

- View

Status

The Status tab displays a number of properties about the part.

- Status: Indicates whether the mesh is closed and oriented.

- Statistics: Lists details about the number of edges, border edges, triangles, inverted orientation, shells, and holes on the part.

- Highlighting: The highlighting section contains controls for making certain features of the part stand out more. Available features to highlight are holes, triangles, edges under a threshold angle, degenerate faces, and errors.

Actions

The Actions tab offers a few details about the part features and also presents several commands to help repair your part.

- Close Holes: Reports the number of border edges and holes in the part. Provides functionality to quickly stitch triangles or remove trivial or all holes.

- Flipped Triangles: Reports the number of triangles with an inverted orientation and provides functionality to quickly fix any flipped triangles.

- Self-Intersections: Provides functionality to detect, split-off, or remove self-intersecting triangles.

Additional repair commands on the Actions tab include Remove Double Triangles, Remove Degenerate Faces, and Wrap Part Surface.

Repair Scripts

The Repair Scripts tab allows you to run, edit, create, and save repair scripts to quickly perform a series of repair operations to your part.

Shells

The Shells tab displays a number of properties about the shells that make up the part. Properties include:

- Triangles

- Area

- Outbox Volume

- Part Volume

- Watertight

- Oriented

- Outbox

View

The View tab provides a number of options to control the visualization of the part features and the selection of surfaces.

- Part: Switches for showing textures (unavailable if the part has no texture) and for viewing the part transparently are located here.

- Show Slim Faces: Provides functionality to color or highlight edges of triangles that are particularly narrow. The slider is used to define the maximum value for the smallest of the inner angles a triangle may have to be considered slim and therefore highlighted. If there are any such triangles present, and in case they do not immediately stand out,

Netfabb also displays this with

Status for Optimization Utility and an icon,

or

or

. Triangles too narrow can cause

Optimization Utility, which operates on a tetrahedral volume mesh to lattice or to lightweight parts, to retriangulate the input surface as this could otherwise produce less reliable results. You cannot control this remeshing in any way except choosing not to, so it can be beneficial to test for this and possibly remesh the part before sending it over.

. Triangles too narrow can cause

Optimization Utility, which operates on a tetrahedral volume mesh to lattice or to lightweight parts, to retriangulate the input surface as this could otherwise produce less reliable results. You cannot control this remeshing in any way except choosing not to, so it can be beneficial to test for this and possibly remesh the part before sending it over.

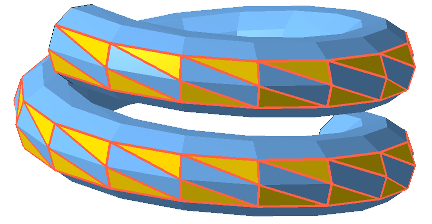

Triangles with their smallest inner angle being smaller than a threshold can be highlighted.

- Surface Selection: When you use the

Select Surfaces mode from the toolbar, and you click a particular triangle, any adjacent triangle that is angled away from the previous one up to this angle becomes selected as well. This is useful for selecting surfaces up to a hard edge, for example, where you would not want a surface selection to "bleed" into areas you do not want to select.

Select Surfaces mode from the toolbar, and you click a particular triangle, any adjacent triangle that is angled away from the previous one up to this angle becomes selected as well. This is useful for selecting surfaces up to a hard edge, for example, where you would not want a surface selection to "bleed" into areas you do not want to select.

Repair module zoom commands

When you enter the repair module, the default zoom commands on the toolbar are changed. The commands available include:

Zoom to Part: The part is centered in the display and the zoom is such that the part fills the screen.

Zoom to Part: The part is centered in the display and the zoom is such that the part fills the screen.

Zoom to Selected Triangles: The selection is centered in the display and the zoom is such that the selection fills the screen.

Zoom to Selected Triangles: The selection is centered in the display and the zoom is such that the selection fills the screen.

Zoom to Selected Area: Allows you to click and drag a window to define the area to zoom into.

Zoom to Selected Area: Allows you to click and drag a window to define the area to zoom into.

Repair module selection info

In the you repair module, a new selection command is presented on the toolbar

-

Show information for selection: Shows details about the selection including the number of triangles selected, the total surface area of the selection, the surface area for the last triangle selected, and the border length for the last triangle selected.

Show information for selection: Shows details about the selection including the number of triangles selected, the total surface area of the selection, the surface area for the last triangle selected, and the border length for the last triangle selected.