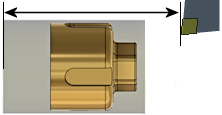

The Face strategy is used for machining the frontside of the part.

|

Access: |

Ribbon:

CAM tab

Turning panel

Turning panel

Face

Face

|

The Face strategy is used for machining the frontside of the part.

Tool tab settings

Tool tab settings

Tool

Select a turning tool from the library, or create a new turning tool.

Coolant

Select the type of coolant that should be used with the tool. Output options will vary depending on the machine capabilities and machine postprocessor configuration.

Use constant surface speed

Enable to automatically adjust the spindle speed to maintain a constant surface speed between the tool and the workpiece as the cutting diameter changes . Constant Surface Speed (CSS) is specified using G96 on most machines.

Surface Speed

The cutting speed expressed as the speed of the tool across the part surface. Expressed as Ft/min or M/min depending on the current Units setting.

Spindle Speed

The rotational speed of the spindle.

Maximum Spindle Speed

Specifies the maximum allowed spindle speed when using Constant Surface Speed (CSS).

Use Feed per Revolution

Enable to switch from Distance over Time (In/Min or MM/min), to Feed Per Revolution (IPR or MMPR). This type of feedrate creates a constant chip load regardless of the spindle RPM.

Cutting Feedrate

Feed used in cutting moves. Input based on the Use Feed per Revolution setting and the current Units.

Lead-In Feedrate

Feed used when leading in to a cutting move. Input based on the Use Feed per Revolution setting and the current Units.

Lead-Out Feedrate

Feed used when leading out from a cutting move. Input based on the Use Feed per Revolution setting and the current Units.

Geometry tab settings

Geometry tab settings

Front Confinement

Used to limit the toolpath by Confining an area. Toolpaths can be contained within a specific region. Front Mode lets you set the reference point for defining the containment area and Offset lets you adjust the boundary positive or negative from that reference. You can use these options to extend the toolpath past the model for a longer cut.

Front Mode

Specifies the reference position for the Front Confinement boundary. These are the options for selecting the reference.

- Stock Front - Allows you to set the reference in relation to the Front of the Stock.

- Stock Back - Allows you to set the reference in relation to the Back of the Stock.

- Chuck Front - Allows you to set the reference in relation to the Chuck Face.

- Model Front - Allows you to set the reference in relation to the Front of the Model.

- Model Back - Allows you to set the reference in relation to the Back of the Model.

- Selected Point - Select a vertex or an edge for the origin reference.

- Origin - Allows you to set the reference in relation to the part Zero position.

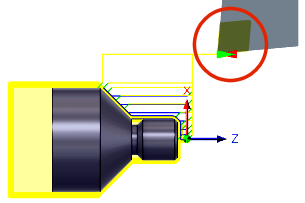

Chuck Front

Offset

Specifies the distance to extend the machining boundary from the reference position shown above. You can specify a positive or negative distance from the reference point, or dynamically drag the position with your mouse. Front boundary is shown in Orange.

Front of Model Reference with .200" Offset

Radii tab settings

Radii tab settings

The Radii tab allows you to set a radial containment area for machining. These parameters are color coded for easy identification.

|

Order for Radii Containment. |

Clearance

Shown in Orange, this controls the radius where the tool rapids to at the start and end of the toolpath. The tool approaches from and retracts to this position.

Shown in Orange, "From" sets the Clearance radius reference position. The reference can be in relation to the Stock, the Model, a specified Radius, Diameter, or any of the other Radial positions. This reference position can be shifted with a positive or negative offset value.

- Retract - Sets the Clearance radius in reference to the Retract Position.

- Stock OD- Sets the Clearance radius in reference to the outside diameter of the defined Stock.

- Model OD - Sets the Clearance radius in reference to the outside diameter of the defined Model.

- Outer radius - Sets the Clearance radius in reference to the Outer radius position. The Clearance radius must be larger than the Outer radius. Use the Offset parameter to make adjustments as needed.

- Inner radius - Sets the Clearance radius in reference to the Inner radius position. The Clearance radius must be larger than the Inner radius. Use the Offset parameter to make adjustments as needed.

- Model ID - Sets the Clearance radius in reference to the inside diameter of the Model, as defined in the Setup. Use the Offset parameter to make adjustments as needed.

- Stock ID - Sets the Clearance radius in reference to the inside diameter of the Stock, as defined in the Setup. Use the Offset parameter to make adjustments as needed.

- Selection - Select any face, vertex, or point on the model to define the Clearance radius. Use the Offset parameter to make positive or negative adjustments as needed..

- Radius - This option allows you to enter a radius value in the Offset field. This value is in reference to the centerline of the part and will not recognize any associative changes to the model.

- Diameter - This option allows you to enter a diameter value in the Offset field. This value is in reference to the centerline of the part and will not recognize any associative changes to the model.

Offset

Use this offset to shift the position relative to the Reference point selected above. You can make positive or negative adjustments as needed.

|

In This Example... |

Retract

Shown in Dark Green, this controls the position above the surface you plan to machine. This is the radius where the tool retracts to between cuts.

Shown in Dark Green, "From" sets the Retract reference position. The reference can be in relation to the Stock, the Model, a specified Radius, Diameter, or any of the other Radial positions. This reference position can be shifted with a positive or negative offset value.

- Clearance - Sets the Retract radius in reference to the Clearance Position.

- Stock OD- Sets the Clearance radius in reference to the outside diameter of the defined Stock.

- Model OD - Sets the Clearance radius in reference to the outside diameter of the defined Model.

- Outer radius - Sets the Clearance radius in reference to the Outer radius position. The Clearance radius must be larger than the Outer radius. Use the Offset parameter to make adjustments as needed.

- Inner radius - Sets the Clearance radius in reference to the Inner radius position. The Clearance radius must be larger than the Inner radius. Use the Offset parameter to make adjustments as needed.

- Model ID - Sets the Clearance radius in reference to the inside diameter of the Model, as defined in the Setup. Use the Offset parameter to make adjustments as needed.

- Stock ID - Sets the Clearance radius in reference to the inside diameter of the Stock, as defined in the Setup. Use the Offset parameter to make adjustments as needed.

- Selection - Select any face, vertex, or point on the model to define the Clearance radius. Use the Offset parameter to make positive or negative adjustments as needed..

- Radius - This option allows you to enter a radius value in the Offset field. This value is in reference to the centerline of the part and will not recognize any associative changes to the model.

- Diameter - This option allows you to enter a diameter value in the Offset field. This value is in reference to the centerline of the part and will not recognize any associative changes to the model.

Offset

Same function as the Clearance Offset shown above.

Outer Radius

Shown in Light Blue, this defines the largest radial boundary of the cutting area. Outer Radius defines the outer stock surface you plan to machine.

|

|

Outer Radius in Light Blue. |

Shown in Light Blue, "From" sets the Outer Radius reference position. The reference can be in relation to the Stock, the Model, a specified Radius, Diameter, or any of the other Radial positions. This reference position can be shifted with a positive or negative offset value.

- Clearance - Sets the Retract radius in reference to the Clearance Position.

- Retract - Sets the Clearance radius in reference to the Retract Position.

- Stock OD- Sets the Clearance radius in reference to the outside diameter of the defined Stock.

- Model OD - Sets the Clearance radius in reference to the outside diameter of the defined Model.

- Inner radius - Sets the Clearance radius in reference to the Inner radius position. The Clearance radius must be larger than the Inner radius. Use the Offset parameter to make adjustments as needed.

- Model ID - Sets the Clearance radius in reference to the inside diameter of the Model, as defined in the Setup. Use the Offset parameter to make adjustments as needed.

- Stock ID - Sets the Clearance radius in reference to the inside diameter of the Stock, as defined in the Setup. Use the Offset parameter to make adjustments as needed.

- Selection - Select any face, vertex, or point on the model to define the Clearance radius. Use the Offset parameter to make positive or negative adjustments as needed..

- Radius - This option allows you to enter a radius value in the Offset field. This value is in reference to the centerline of the part and will not recognize any associative changes to the model.

- Diameter - This option allows you to enter a diameter value in the Offset field. This value is in reference to the centerline of the part and will not recognize any associative changes to the model.

Offset

Same function as the Clearance Offset shown above.

Inner Radius

Shown in Dark Blue, this defines the smallest radial boundary of the cutting area. Inner Radius controls the maximum depth for the cut area .

|

|

Inside Radius in Dark Blue. |

Shown in Dark Blue, "From" sets the Inner Radius reference position. The reference can be in relation to the Stock, the Model, a specified Radius, Diameter, or any of the other Radial positions. This reference position can be shifted with a positive or negative offset value.

Same as the Outer Radius "From" options shown above.

Offset

Same function as the Clearance Offset shown above.

Passes tab settings

Passes tab settings

Tolerance

The machining tolerance is the sum of the tolerances used for toolpath generation and geometry triangulation. Any additional filtering tolerances must be added to this tolerance to get the total tolerance.

Loose Tolerance .100

Tight Tolerance .001

CNC machine contouring motion is controlled using line G1 and arc G2 G3 commands. To accommodate this, CAM approximates spline and surface toolpaths by linearizing them; creating many short line segments to approximate the desired shape. How accurately the toolpath matches the desired shape depends largely on the number of lines used. More lines result in a toolpath that more closely approximates the nominal shape of the spline or surface.

Data Starving

It is tempting to always use very tight tolerances, but there are trade-offs including longer toolpath calculation times, large G-code files, and very short line moves. The first two are not much of a problem because Inventor CAM calculates very quickly and most modern controls have at least 1MB of RAM. However, short line moves, coupled with high feedrates, may result in a phenomenon known as data starving.

Data starving occurs when the control becomes so overwhelmed with data that it cannot keep up. CNC controls can only process a finite number of lines of code (blocks) per second. That can be as few as 40 blocks/second on older machines and 1,000 blocks/second or more on a newer machine like the Haas Automation control. Short line moves and high feedrates can force the processing rate beyond what the control can handle. When that happens, the machine must pause after each move and wait for the next servo command from the control.

Compensation Type

Specifies the compensation type.

- In computer - Tool compensation is calculated automatically by Inventor CAM, based on the selected tool diameter. The post-processed output contains the compensated path directly, instead of G41/G42 codes.

- In control - Tool compensation is not calculated, but rather G41/G42 codes are output to allow the operator to set the compensation amount and wear on the machine tool control.

- Wear - Works as if In computer was selected, but also outputs the G41/G42 codes. This lets the machine tool operator adjust for tool wear at the machine tool control by entering the difference in tool size as a negative number.

- Inverse wear - Identical to the Wear option, except that the wear adjustment is entered as a positive number.

Multiple Passes

Enable to enter a stepover value.

Number of Stepovers

The number of roughing steps.

Stepover

Specifies the distance between passes. By default, this value is 95% of the cutter width less the tool corner radius.

Stepover between cuts

Finishing Passes

Enable to perform finishing passes using the side of the tool.

Finishing passes on

Finishing passes off

Multiple Finishing Passes

Enable to specify more than one finishing pass. If Finishing Passes is enabled, but Multiple Finishing Passes is disabled, then only one finishing pass is performed.

Multiple finishing passes on

Multiple finishing passes off

Number of Finishing Passes

Specifies the number of finishing passes.

Shown with three finishing passes

Stepover

The maximum distance between finishing passes.

Stock to Leave

Positive

Positive Stock to Leave - The amount of stock left after an operation to be removed by subsequent roughing or finishing operations. For roughing operations, the default is to leave a small amount of material.

None

No Stock to Leave - Remove all excess material up to the selected geometry.

Negative

Negative Stock to Leave - Removes material beyond the part surface or boundary.

Axial (face) Stock to Leave

The Axial Stock to Leave parameter controls the amount of material to leave in the axial direction (along the Z-axis), i.e. On the faces of flanges. Specifying a positive Axial stock to leave results in material being left on the Faces and shallow areas in the Z direction.

Axial stock to leave

For finishing operations, it's common to set the default value to 0 mm / 0 in, i.e. no material is left.

For roughing operations, it's common to leave a small amount of material that can then be removed later by one or more finishing operations.

Negative stock to leave

When using a negative stock to leave, the machining operation removes more material from your stock than your model shape. This can be used to machine electrodes with a spark gap, where the size of the spark gap is equal to the negative stock to leave.

Both the radial and axial stock to leave can be negative numbers. However, the negative radial stock to leave must be less than the tool radius. When using a large nose radius or a button type insert with a negative stock, the negative stock must be less than or equal to the radius.

Linking tab settings

Linking tab settings

|

|

|

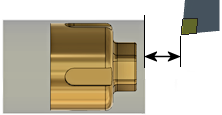

Retraction Policy

Controls how the tool should retract to the clearance diameter after every cutting pass. or just retract a short distance away from the job. The distance is determined by the Safe Distance value.

-

Full retraction - completely retracts the tool to the

Retract Height at the end of the pass before moving above the start of the next pass.

Full retraction

-

Minimum retraction - moves straight up to the lowest height where the tool clears the workpiece, plus any specified safe distance.

Minimum retraction

High Feedrate Mode

Specifies when rapid movements should be output as true rapids (G0) and when they should be output as high feedrate movements (G1).

- Preserve rapid movement - All rapid movements are preserved.

- Preserve axial and radial rapid movement - Rapid movements moving only horizontally (radial) or vertically (axial) are output as true rapids.

- Preserve axial rapid movement - Only rapid movements moving vertically.

- Preserve radial rapid movement - Only rapid movements moving horizontally.

- Preserve single axis rapid movement - Only rapid movements moving in one axis (X, Y or Z).

- Always use high feed - Outputs rapid movements as (high feed moves) G01 moves instead of rapid movements (G0).

This parameter is usually set to avoid collisions at rapids on machines which perform "dog-leg" movements at rapid.

High Feedrate

The feedrate to use for rapids movements output as G1 instead of G0.

Approach and Retract

Used to define how the tool should position at the start of the operation and the end of the operation. The default position is in reference to the Safe Z as defined in the Setup. You can override the Setup Safe Z position with the options shown below.

- Safe Z - The Approach position will be the same as the Safe Z position defined in the Setup.

- First Toolpath Position - The Approach position will be the same as the first Z position of the toolpath.

Approach Z - Defines how the tool will position before the start of the toolpath.

- Safe Z - The Approach position will be the same as the Safe Z position defined in the Setup.

- Last Toolpath Position - The Retract position will be the same as the Last Z position of the toolpath.

Retract Z - Defines how the tool will position after completing the toolpath.

Override Setup Safe Z

Enable to redefine the Reference position for the Safe Z retract.

- Setup WCS Origin - Set reference to the Work Coordinate Offset position set in the Setup

- Stock Front - Set the reference to the Stock Font position

- Stock Back - Set the reference to the Stock Back position

Safe Z Reference - Select the new reference position to set the Safe Z retract.

Safe Z Offset

Set the distance to shift from the reference position specified above.

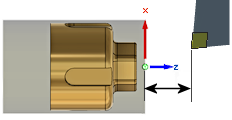

WCS Reference and Offset Distance |

WCS Reference and Offset Distance |

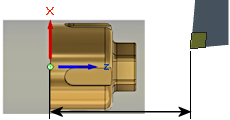

Stock Front Reference and Offset Distance |

Stock Back Reference and Offset Distance |

Lead-In (Entry)

Enable to generate a lead-in.

Lead-in

Lead-In Radius

Specifies the radius of the lead-in move at the start of a cutting pass.

Lead-In Radius @ 0mm

Lead-In Radius @ 3mm

Linear Lead-In Length

Specifies the distance (length) of the lead-in move at the start of a cutting pass.

Linear Lead-In Distance set to 1mm

Linear Lead-In Distance set to 5mm

Linear Lead-In Angle

Specifies the angle of the lead-in move at the start of a cutting pass. Note that the angle reference depends on the Use Fixed Lead direction.

Lead-In Angle @ 45 degrees

Lead-In Angle @ 90 degrees

Lead-Out (Exit)

Enable to generate a lead-out.

Lead-out

Same as Lead-In

Specifies that the lead-out definition should be identical to the lead-in definition.

Linear Lead-Out Distance

Specifies the distance (length) of the lead-out move at the end of a cutting pass.

Linear Lead-Out Distance set to 1 mm

Linear Lead-Out Distance set to 5 mm

Lead-Out Radius

Specifies the radius of the lead-out move at the end of a cutting pass.

Lead-Out Radius @ 0mm

Lead-Out Radius @ 3mm

Linear Lead-Out Angle

Specifies the angle of the lead-out move at the end of a cutting pass. Note that the angle reference depends on the Use Fixed Lead direction.

Lead-Out Angle @ 45 degrees

Lead-Out Angle @ 90 degrees