Next, clear the base surfaces where they are perfectly horizontal.

- On the ribbon, click

CAM tab

3D Milling panel

3D Milling panel

Horizontal

Horizontal

.

.

Tool tab

Tool tab

- On the Tool tab, click the

button.

button. - Select the tool #13 - Ø6 R1 mm bullnose from the Tutorial4 library.

- Click

to close the Tool Library dialog.

to close the Tool Library dialog.

Heights tab

Heights tab

By default, the Horizontal finishing strategy also machines across the top of the part and the small flat areas on the ridges of the part. In this operation we are only concerned about the bottom flat face, and so we can limit the depth range that is to be machined.

- Click the Heights tab.

- From the Top Height drop-down menu, choose Selection.

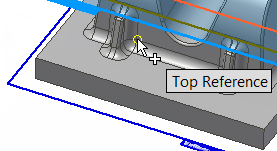

- For the Top reference, select one of the vertices above the bottom fillet as shown below.

Passes tab

Passes tab

- Click the Passes tab.

- Set Tolerance: to: 0.02 mm

- Set Smoothing deviation: to: 1 mm

- Enable the Stock to Leave check box. This operation machines down to the final shape of the part, without any stock allowance.

- Set Radial stock to leave to: 0 mm

- Set Axial stock to leave to: 0 mm (this value should update automatically)

Start the Calculation

- Click

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

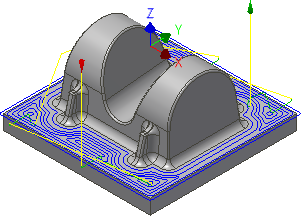

The toolpath is now calculated and a preview appears in the graphics window.

Continue to To Machine Fillets Using Pencil Milling...