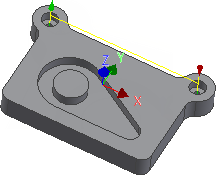

The next step is to drill the two small holes at the top left and right corners of the work piece.

- On the ribbon, click

CAM tab

Drilling panel

Drilling panel

Drill

Drill

.

.

Tool tab

Tool tab

Change the default tool.

- On the

Tool tab, click the

button.

button.

- Click the

button.

button.

- Click the Cutter tab.

- Change Type to Drill by selecting it from the drop-down menu.

- Change Diameter to 5 mm.

- Click the OK button to create your new tool.

- Click the Select button to select the tool for your operation and close the Tool Library dialog.

This procedure creates a tool with default dimensions and cutting data. The default is a Ø10 mm drill. We will use most of the defaults, but change some of the cutting parameters a bit.

Geometry tab

Geometry tab

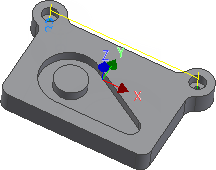

- Click the Geometry tab. Ensure that Selected faces is selected from the Hole mode: drop-down menu and that the Hole faces selection button is active.

- Zoom in, and select the cylindrical face of the smaller diameter hole at the top left corner of the part.

- Enable the

Select same diameter check box. Doing so automatically selects the identically sized small hole at the top right of the part.

Heights tab

Heights tab

- Click the Heights tab and enable the Drill tip through bottom check box.

- Change Break-through depth to: 1 mm

Cycle tab

Cycle tab

- Click the Cycle tab.

- Select Chip breaking - partial retract from the Cycle type: drop-down menu.

Start the Calculation

- Click

at the bottom of the

Operation dialog box, or right-click in the graphics window and select

OK from the marking menu, to automatically start calculating the toolpath.

at the bottom of the

Operation dialog box, or right-click in the graphics window and select

OK from the marking menu, to automatically start calculating the toolpath.

Continue to To Tap Holes...