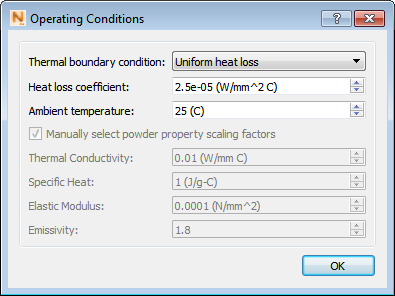

The Operating Conditions menu allows users to set the thermal conditions of the model.

There are three Thermal boundary condition options:

- Uniform Heat Loss - This is the default option. This applies a constant convection boundary condition to all the surfaces of the part and build plate.

- Conduction to Loose Powder - This option can produce more accurate model results for geometries with thinly spaced features or for closely packed parts by modeling the powder directly. However the addition of powder elements can add significant complexity to the model which can add significant computational expense in the form of additional memory requirements and simulation time. When implementing this boundary condition the Build Plate Size should be extended in all 4 directions so that powder elements can be used to surround the part, allowing the thermal energy to dissipate into the modeled powder.

- Estimated Heat Loss - This estimates the heat loss into the powder as a constant heat flux based upon the room temperature material conductivity.

| Uniform Heat Loss | Conduction to Loose Powder |

|---|---|

| 33086 Nodes

15856 Elements 727892 Layer-Nodes |

67751 Nodes

46668 Elements 1490522 Layer-Nodes |

| 44 second thermo-mechanical runtime on 14 core machine | 72 second thermo-mechanical runtime on 14 core machine |

Specify the Heat loss coefficient to control the surface heat losses. If using the Uniform Heat Loss this will be the uniform value applied to the external faces of the build plate and component; if using Conduction to Loose Powder, this will be the value applied to the build plate, exposed component, and powder surfaces. If using Estimated Heat Loss, the convection coefficient value will be automatically calculated and applied to all external faces of the build plate and built material. The value calculated will be recorded to the thermal log file.

Use the Ambient temperature field to set the environmental temperature inside the powder bed machine during processing.

If Conduction to Loose Powder has been selected, users can manually select the property scaling properties that are used to estimate the thermal and mechanical properties of the powder from the component material properties.