Description

The MATB entry specifies a brittle failure material. Tensile cracks form in the orthogonal principal strain directions based upon the tensile strength provided. In compression, the model can behave as an elastic material, an elastic/perfectly plastic material, or as an elastic/plastic strain softening material.

This model can also be used to specify a “no tension” material by setting the tensile strength to zero.

Format

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| MATB | MID | E | G | NU | RHO optional | A optional | optional | optional | optional |

| CMODEL | TS | CS | TMULT | CMULT optional | optional | optional | optional | optional |

Example

| MATB | 35 | 5.E6 | 0.18 | 1.e-4 | |||||

| 1 | 100 | 2000 | 3 | 9 |

| Field | Definition | Type | Default |

|---|---|---|---|

| MID | Material identification number | Integer > 0 | Required |

| E | Young's modulus | Real ≥ 0.0 or blank | See Remark 3 |

| G | Shear modulus | Real ≥ 0.0 or blank | See Remark 3 |

| NU | Poisson's ratio | -1.0 < Real ≤ 0.5 or blank | See Remark 3 |

| RHO | Mass density | Real ≥ 0.0 | Required |

| A | Thermal expansion coefficient | Real or blank | 0.0 |

| CMODEL | Compression behavior:

1 = Elastic Compression 2 = Elastic/Perfectly Plastic Compression 3 = Elastic/Plastic Strain Softening Compression |

Integer > 0 | 1, See Remark 5 |

| TS | Tensile strength | Real ≥ 0.0 | Required; See Remark 4 |

| CS | Compressive strength | Real ≥ 0.0 or blank | 1.E30; See Remark 6 |

| TMULT | Tensile deletion strain multiplier | Integer ≥ 1 | 1000; See Remarks 7 and 9 |

| CMULT | Compression deletion strain multiplier | Integer ≥ 1 | 1000; See Remarks 8 and 9 |

Remarks

- The material identification number must be unique for all MATi entries.

- Either E or G must be specified (not blank).

- If any one of E, G, or NU is blank, it will be computed to satisfy the identity E = 2(1 + NU)G; otherwise, values supplied by the user will be used.

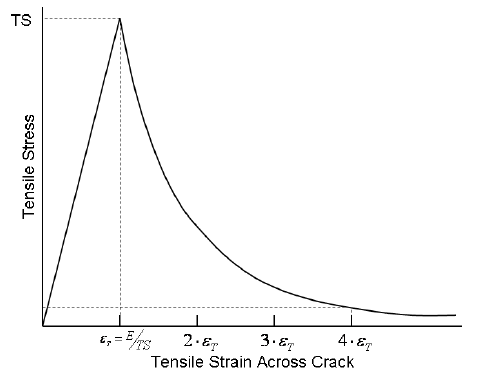

- The tensile behavior of the material is purely elastic up to the tensile strength value. Individual cracks can form in orthogonal principal strain directions. The stress strain curve in tension strain softens after cracking occurs as shown in Figure 1.

Figure 1: Tensile Stress/Strain curve

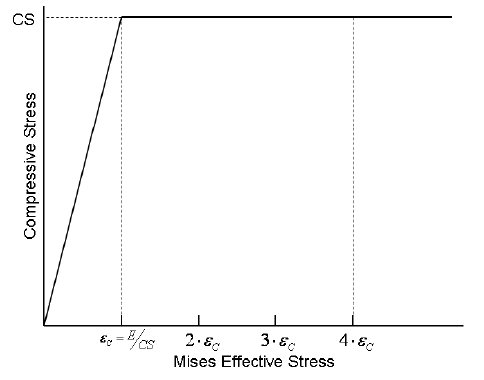

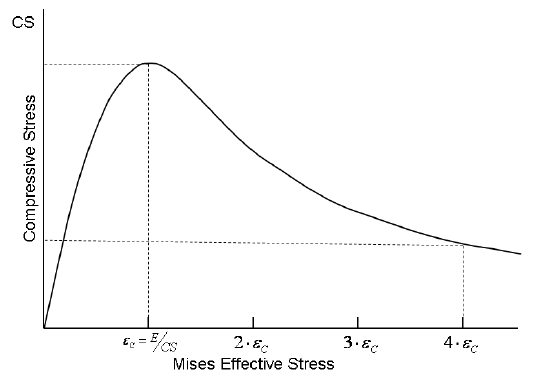

- The compressive behavior of the material may either be Elastic (Hooke’s Law), Elastic/Perfectly-Plastic (Figure 2) or Elastic/Plastic Strain Softening (Figure 3).

Figure 2: Elastic/Perfectly Plastic Compression Model (CMODEL = 2)

Figure 3: Elastic/Plastic Strain Softening Model (CMODEL = 3 )

- A compressive strength value is only required if CMODEL = 2 or 3. The default value of 1.E30 implies infinite strength.

- The tensile strain at which the material point is deleted from the mesh (if the BRITTLE deletion criteria was specified for this part PID) is determined from this multiple of the failure strain. In Figure 1, the deletion strain is shown for TMULT = 4. The default value of 1000 implies no element deletion in the material.

- The compressive strain at which the material point is deleted from the mesh (if the BRITTLE deletion criteria was specified for this part PID) is determined from this multiple of the failure strain. In Figures 2 and 3, the deletion strain is shown for CMULT = 4. The default value of 1000 implies no deletion in the material.

- The deletion strains defined by TMULT and CMULT have no effect unless the BRITTLE element DELETION option is specified for this part PID.