Use the Corner pencil finishing page to create a single trace toolpath to clean up corners that occur between non-tangential surfaces.

Output —Select which portions of the toolpath you want to generate.

- Steep — Outputs the portion of the toolpath, which makes an angle of at least the Threshold angle to the horizontal.

- Shallow — Outputs the portion of the toolpath, which makes an angle of up to the Threshold angle to the horizontal.

- Both — Outputs both the steep and shallow portions.

Threshold angle — Enter an angle, from the horizontal, at which steep and shallow portions are split when you select an Output type of Steep or Shallow.

Detection limit — Enter an angle so that PartMaker machines only corners that are sharper than this angle. 165 is the default value. This works well for most corners. However there are instances where you need to increase this value to detect the corner regions in which you are interested.

is the default value. This works well for most corners. However there are instances where you need to increase this value to detect the corner regions in which you are interested.

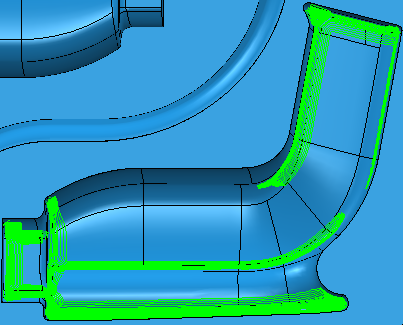

- With a Detection limit of 165

:

:

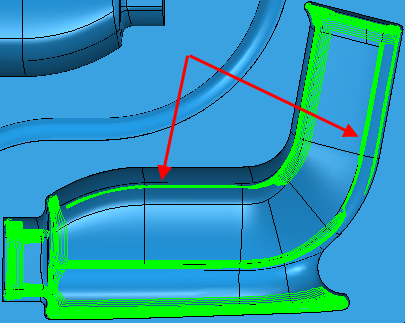

- With a Detection limit of 170

:

:

Tolerance — Enter a value to determine how accurately the toolpath follows the contours of the model.

Cut direction — Select the milling technology.

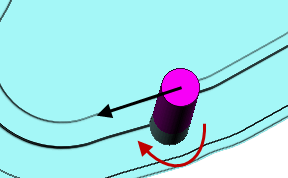

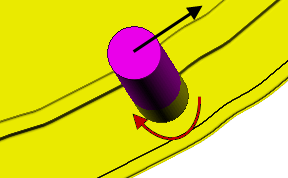

- Climb — Select to create toolpaths using only climb milling, where possible. The tool is on the left of the machined edge when viewed in the direction of tool travel.

- Conventional — Select to create toolpaths using only conventional or upcut milling, where possible. The tool is on the right of the machined edge when viewed in the direction of tool travel.

- Any — Select to create toolpaths using both conventional and climb milling, as appropriate. This minimizes the tool lifts and tool travel.

Thickness — Enter the amount of material to be left on the stock within tolerance. Thickness is applied as an offset to the tool in all directions: