Use the Corner finishing page to create a multiple trace toolpath to clean up corners that occur between non-tangential surfaces. Using the Style setting, you can specify whether the toolpath follows the trace lines or cuts across them. The Corner Detection page determines the extents of the toolpath.

Output —Select which portions of the toolpath you want to generate.

- Steep — Outputs the portion of the toolpath, which makes an angle of at least the Threshold angle to the horizontal.

- Shallow — Outputs the portion of the toolpath, which makes an angle of up to the Threshold angle to the horizontal.

- Both — Outputs both the steep and shallow portions.

Style — Select how to generate the toolpath on the trace lines.

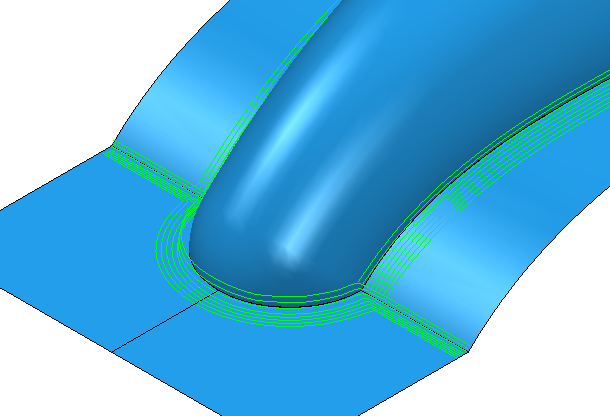

- Along — Select to create a corner toolpath which follows the trace lines. This is best suited to shallow regions.

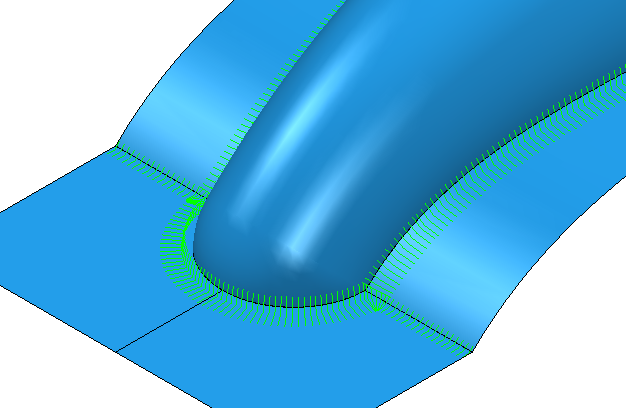

- Stitch — Select to create a corner toolpath which cuts across the trace lines. This is best suited to steep regions.

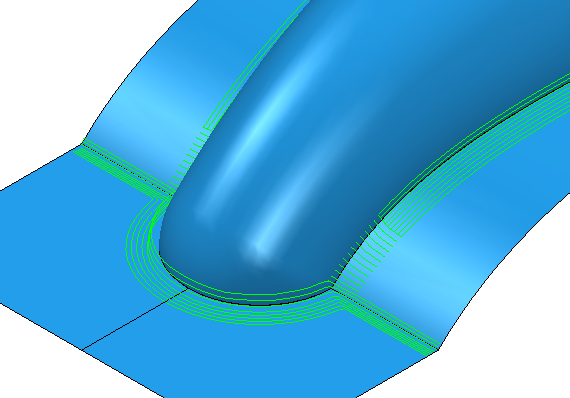

- Automatic — creates a corner toolpath which produces stitches on the Steep areas and along passes on the Shallow areas.

Threshold angle — Enter an angle, from the horizontal, at which steep and shallow portions are split when you select an Output type of Steep or Shallow.

Cusp — Enter the cusp height. PartMaker calculates the stepover between tool passes using the cutter geometry and this cusp height.

Tolerance — Enter a value to determine how accurately the toolpath follows the contours of the model.

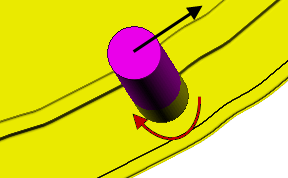

Cut direction — Select the milling technology.

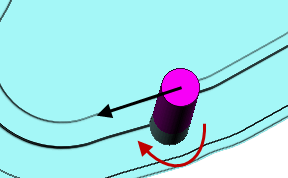

- Climb — Select to create toolpaths using only climb milling, where possible. The tool is on the left of the machined edge when viewed in the direction of tool travel.

- Conventional — Select to create toolpaths using only conventional or upcut milling, where possible. The tool is on the right of the machined edge when viewed in the direction of tool travel.

- Any — Select to create toolpaths using both conventional and climb milling, as appropriate. This minimizes the tool lifts and tool travel.

Thickness — Enter the amount of material to be left on the stock within tolerance. Thickness is applied as an offset to the tool in all directions: