The Process Table contains all the cutting processes required to machine the part.

In PartMaker/WireEDM, the Process Table displays the following information:

Process Table toolbar

Use the Process Table toolbar to perform actions on the processes in the Process Table.

The following buttons are available in PartMakerWireEDM.

— Displays the

Simulation window, where you can visualize the part being machined and identify any errors before machining.

— Displays the

Simulation window, where you can visualize the part being machined and identify any errors before machining.

— Click

— Click

to display options for controling the display of columns:

to display options for controling the display of columns:

- Full View — Select to display equally spaced columns using all the available space.

- Default View— Select to position the columns in their default positions.

— Click

— Click

to display options for the

Status column in the Process Table. When the

Status option is selected for a process,

PartMaker includes the process in simulation and postprocessing.

to display options for the

Status column in the Process Table. When the

Status option is selected for a process,

PartMaker includes the process in simulation and postprocessing.

- Show Process Status/Hide Process Status — Select to show or hide the Status column in the Process Table.

- Enable All Processes — Select to enable the Status option for all processes.

- Disable All Processes — Select to disable the Status option for all processes.

Window Position — Set the position of the Process Table window:

Window Position — Set the position of the Process Table window:

- Float — Select to open this window as a separate instance so it is not limited to within the PartMaker window and can be moved between monitors.

- Dock — Select to keep this window within the main PartMaker window.

Process details

The Process Table displays the following details about the processes in the table:

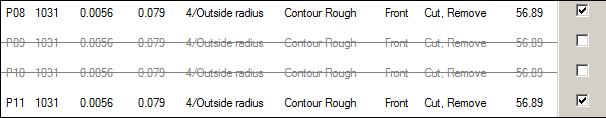

Proc ID —The process's unique identifier (ID).

Power — The power setting for the process.

Offset — The distance between the wire and the part for the process.

Feed — The wire feed rate used for the process.

Group — The name of the Group that contains the toolpath for this process.

Operation — The type of operation performed by this process, for example Contour Roughing.

Face — The name of the Face window that contains the Group for this process.

Options — The options that have been selected for this process. You can specify whether the slug must be removed after a process or the whether the wire must be cut using the options on the Process Parameters dialog.

Also, if you select the Cut Wire Automatically option on the Process Table Options dialog, PartMaker automatically cuts the wire after each roughing operation and in between processes that work on different profile curves.

Time — The time it takes to perform the process on the machine.

Status — When the Status option is selected for a process, PartMaker includes the process in simulation and in postprocessing.

You can select or deselect individual processes by clicking the Status check box for that process.

To enable or disable the Status option for all processes in the table, click

on the Process Table toolbar:

on the Process Table toolbar:

- Select Enable All Processes to select the Status option for all processes in the table.

- Select Disable All Processes to de-select the Status option for all processes in the table.

PartMaker uses a strikethrough to denote processes that are excluded from simulation and postprocessing. For example:

Job details

The Process Table also enables you to view details of the time required to machine the part:

Material Name — The material used for the part.

Wire — The wire used to machine the part.

Total Cutting Length — The total length of the cut to be made.

Total Time — The total time it takes to machine the part.