Use the First lead in page to specify a First lead in move that is different from the subsequent lead in moves.

Use a separate first lead in — Select this option to specify a different First lead in move.

This example uses a Lead in and Lead out of Surface normal arc.

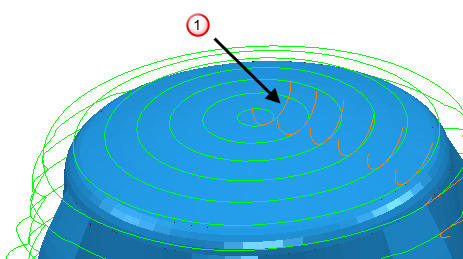

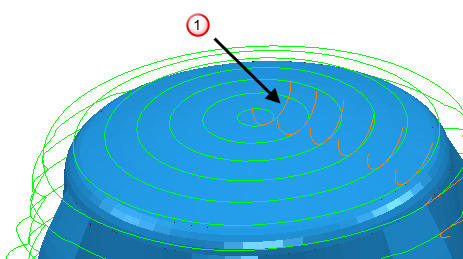

Use a separate first lead in deselected:

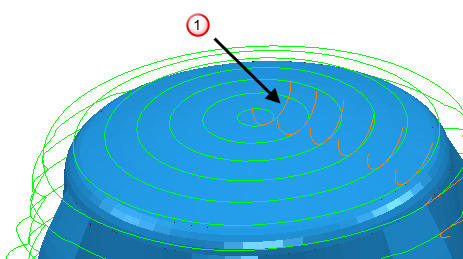

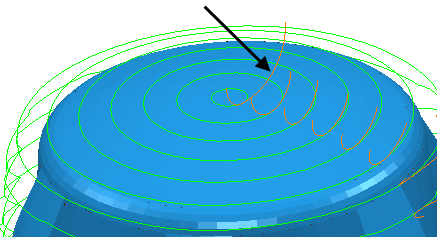

A First lead in of Surface normal arc with a Distance of 0, an Angle of 90 and a Radius of 5.

A First lead in of Surface normal arc with a Distance of 0, an Angle of 90 and a Radius of 5.

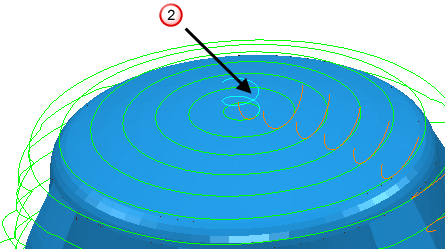

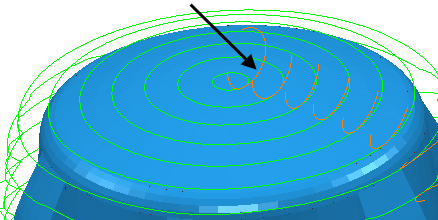

Use a separate first lead in selected:

A First lead in of Ramp (where the ramp follows the toolpath).

A First lead in of Ramp (where the ramp follows the toolpath).

Type — Select the type of Lead in move to use at the start of the toolpath.

Distance — Enter the distance to extend the First lead in move before the cutting move starts. If this is an arc move, then the distance is the length of the linear tangential move between the arc and the cutting portion of the toolpath.

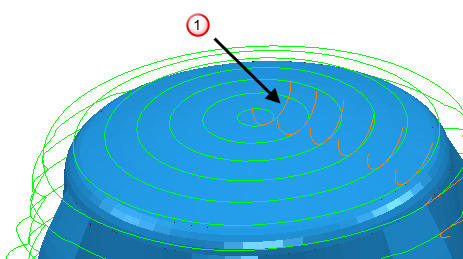

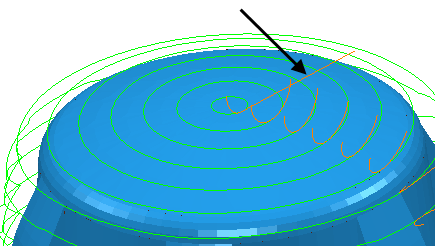

- With a Distance of 0:

A First lead in of Surface normal arc with a Distance of 0, an Angle of 90 and a Radius of 5.

A First lead in of Surface normal arc with a Distance of 0, an Angle of 90 and a Radius of 5. - With a Distance of 10:

Angle — Enter the angle of the First lead in move relative to the first toolpath segment. For arcs, this is the angle spanned by the arc. For lines, it is the orientation relative to the cutting move.

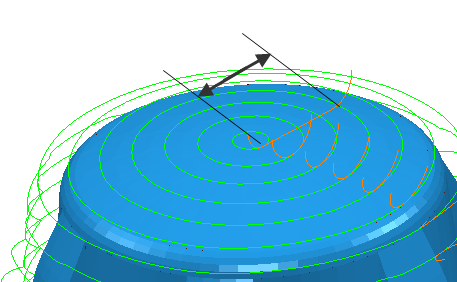

- With an Angle of 90

:

:

A First lead in of Surface normal arc with a Distance of 0, an Angle of 90 and a Radius of 5.

A First lead in of Surface normal arc with a Distance of 0, an Angle of 90 and a Radius of 5. - With an Angle of 180

:

:

For a First lead in of Straight and Angle of 0

:

:

- With an Angle of 90

:

:

Radius — Enter the radius of the First lead in arc move.

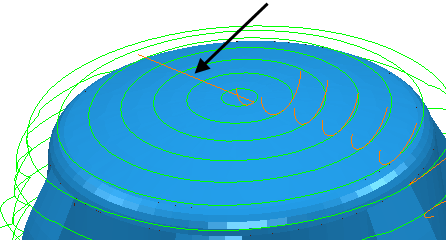

- With a Radius of 5:

A First lead in of Surface normal arc with a Distance of 0, an Angle of 90 and a Radius of 5.

A First lead in of Surface normal arc with a Distance of 0, an Angle of 90 and a Radius of 5. - With a Radius of 10:

Ramp Options — Click to display the Ramp Options dialog, where you can specify how the tool ramps into the stock when using a Ramp-type move. This is available only when a Ramp move is selected.