Vortex machining is an area clearance strategy that rapidly removes material from a 3D part while controlling tool load. Vortex is best suited to solid carbide tools and is frequently used in combination with step cutting.

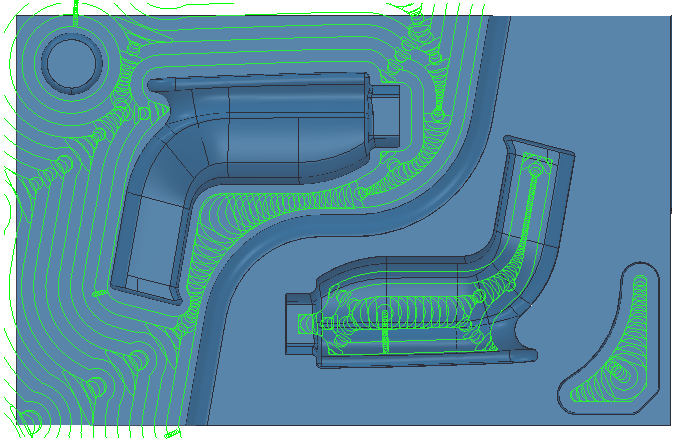

It is an offset-style toolpath and has these main features:

- The engagement angle never exceeds, by more than 15%, that produced by a straight line cut with a given stepover. This eliminates excessive tool load and all full-width cuts. This enables you to increase feed rates. For other area clearance toolpaths, the cutting values are based on the tool manufacturer's slot cutting parameters to ensure the tool can sustain full cutting engagement. As the tool approaches the maximum engagement angle for optimum machining, the toolpath changes to a trochoidal path to avoid tool overload.

- The machine tool almost always runs at the specified feed rate. With other area clearance toolpaths, the machine tool automatically slows down as it approaches a corner and the engagement angle increases. Vortex modifies the toolpath so the tool engagement angle is never exceeded and the machine tool achieves the specified feed rate. The only time the machine tool doesn't run at the specified feed rate is when the model geometry (a slot or corner) is smaller than the smallest radius that the machine can run at full speed.

- Vortex machining cuts with the side of the tool so it is designed for solid carbide tools, but you may be able to use other tools.

- Because PartMaker controls the tool engagement, you can increase the depth of cut which minimizes machining time.

- Vortex machining is frequently used in combination with Step cutting to minimize terracing while maximizing the removal rate.

- Vortex toolpaths are automatically checked for safety. PartMaker checks for:

- plunges into stock.

- excess tool engagement.

- excess depth of cut.

- small arc movements.

To maximize the benefits of Vortex machining:

- Configure the Vortex parameters to suit each machine tool.

- Use Step cutting to minimize terracing caused by the increased depth of cut.

With optimum settings, Vortex machining greatly reduces machining times.