Use the Spiral finishing page to specify settings for a 2D spiral pattern within a boundary, which is projected onto the model. This pattern is then machined.

This strategy minimizes the number of tool lifts, while maintaining more constant load conditions and deflections on the tool. This maximizes cutting time, which in turn reduces the overall machining time.

Center point —Enter values to define the origin of the spiral pattern.

Radius — Enter values to control the dimensions of the pattern and determine whether the tool moves inwards towards the center of the spiral or outwards away from the center. If the end radius is greater than the start radius, the tool will move outwards, otherwise it will move inwards.

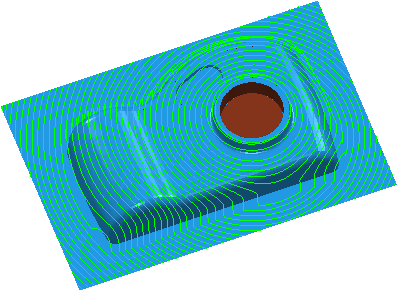

- With a Radius Start of 20 and a Radius End of 135.

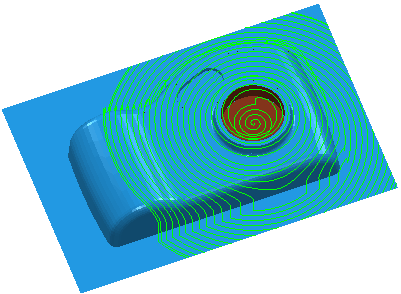

- With a Radius Start of 0 and a Radius End of 80.

Stepover — Enter the distance between successive machining passes.

Tolerance — Enter a value to determine how accurately the toolpath follows the contours of the model.

Direction — Select the direction of the toolpath. There are two options: Clockwise and Counter-clockwise.

Thickness — Enter the amount of material to be left on the stock within tolerance. Thickness is applied as an offset to the tool in all directions: