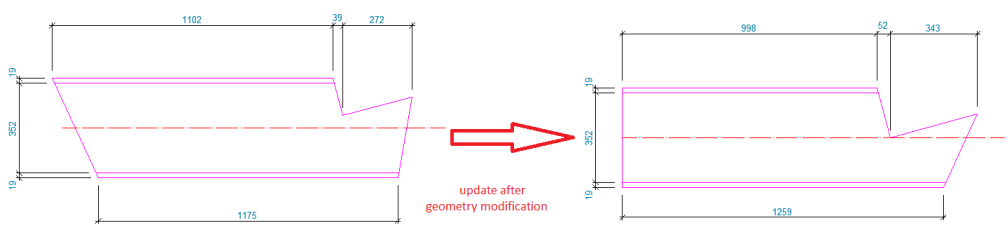

Manual dimensions can be updated after any geometry change that affects their value. This behavior applies in most situations, when certain snap points are used during the manual dimension, while other snap points are not supported. If a snap point is not accepted by the smart manual dimension update, then Advance Steel displays the following error message after the line is created:

Error: Unable to recognize all points. Some Points will be deleted after detail.

The cases supported by the manual smart dimensions are the following:

- End points - when taken on the object contour

- Any end point on it (including the contour defined by features) is recognized by smart dimensions, and if the model has any modifications (features change position/shape or are removed), the manual dimension will update.

- System line end points

- Can be dimensioned with the snap point Node or End point.

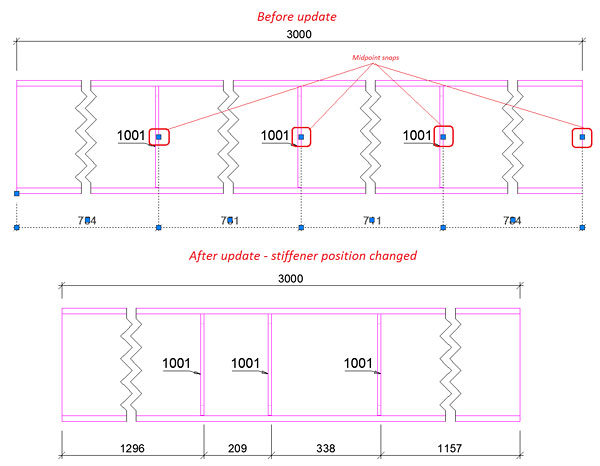

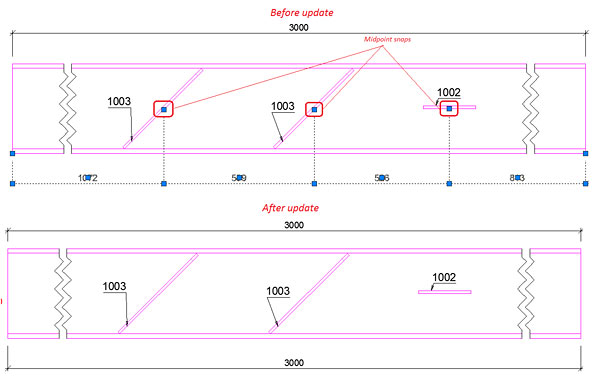

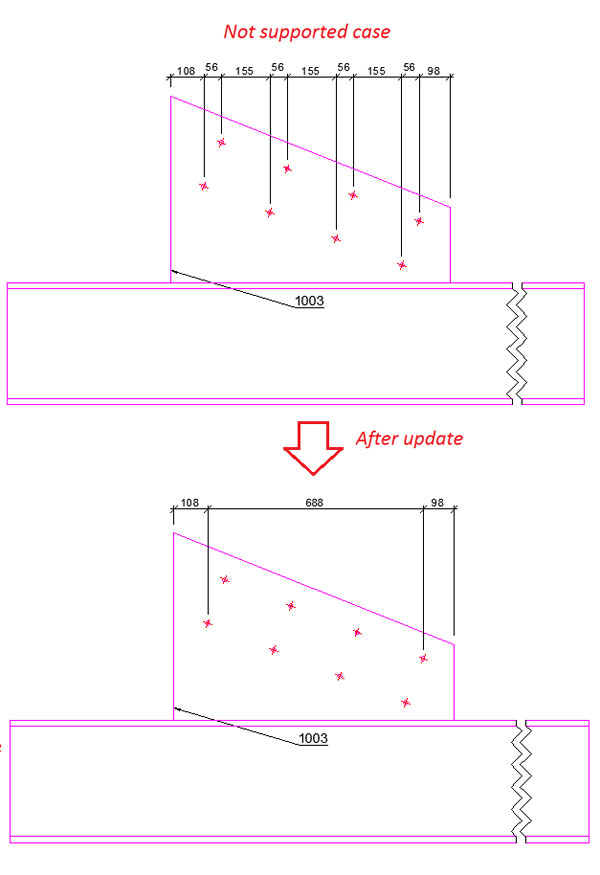

- Midpoints when taken on edges perpendicular on the dimension direction

-

- Note: After update, the snap points that were taken on the midpoint move to the closest dimension line end point of the object on which the midpoint was initially chosen, location change does not affect the correct dimension value.If the midpoint is taken on an edge which is not perpendicular on the dimension direction, then the dimension points are removed after update.

-

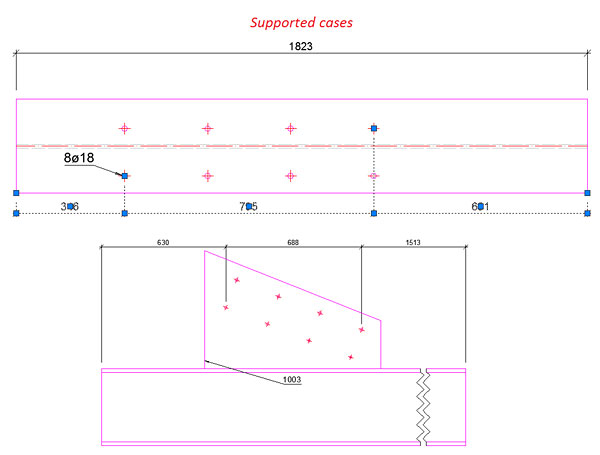

- Center snap points

- Are used for hole/bolt dimensioning.

- Using smart dimensions with center snap points on hole/bolt patterns can be done in the following two cases:

-

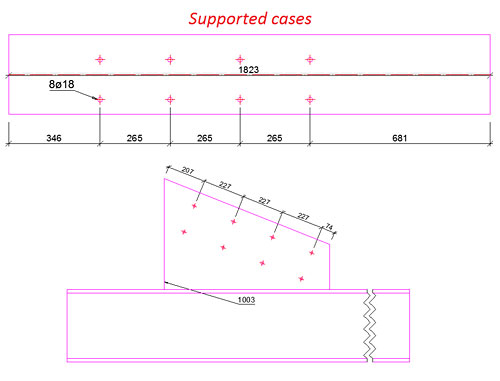

The dimension line is created on two holes/bolts that mark the extremities of the pattern, in the dimension direction.

If there is more than one hole/bolt at one extremity, then any of them is supported, and the dimension line does not change to a similar hole during update.

Only one dimension point can be taken from the hole/bolt pattern as long as it is at one of the extremities of the hole/bolt pattern in the dimensioning direction.

If any of the two points is incorrectly picked, then it will be removed during the update without affecting the other dimension points in that chain.

Any additional hole/bolt center snap points chosen from in between the extremities, as long as we do not choose all of them (see next point), are removed during update without affecting the correct snap points.

-

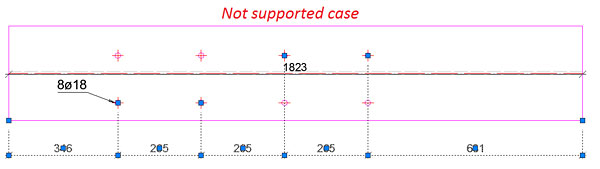

The dimension line is created on all the holes/bolts forming a pattern

In this case, if additional bolts/holes are added to the pattern, the manual smart dimension updates and dimensions these bolts/holes as well, even if a point for them was not picked during the initial dimension creation.

The holes/bolts picked must be on the same side of the pattern, otherwise the intermediary points are removed during update.

Also, the dimension direction must match the bolt/hole pattern direction; otherwise the intermediary points are removed during update.

Angle dimensions: the condition is to use an End Point snap for the start of the 0-line, while the end of the 0-line, and the dimensions points can be created by using the "End point" snap point or the "Nearest" snap point.

-

The dimension line is created on two holes/bolts that mark the extremities of the pattern, in the dimension direction.