The bolt mapping feature allows Advance Steel to utilize a user-configured name for a specific bolt. This name can be used in both BOM lists and drawing labels through a special token that evaluates the mapped name and displays it.

The main required steps to create and use a bolt mapping are: setting the mapping priority, configuring the mapping and then the BOM template / label configuration for the derived document.

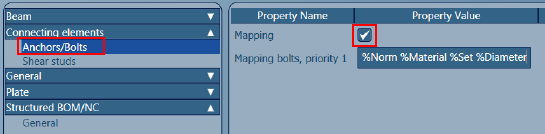

First, turn on the mapping by checking the Mapping default from the Management Tools / Defaults / Connecting elements / Anchors/Bolts.

Configuring the mapping priority

The mapping priority is a series of tokens that form the name of the bolt that takes its mapping from the specific configuration.

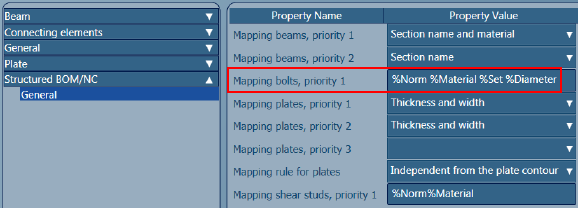

This setting is a default value available in the Management Tools / Defaults / Structured BOM/NC category. The default name is Mapping bolts, priority 1.

For example, if you need for each different bolt class, material, set and diameter to get a different mapping, you need to set the default that controls the priority as follows: %Norm %Material %Set %Diameter.

The tokens that you can use to configure this default are:

- %Norm - bolt class name

- %Diameter

- %Set - assembly set

- %Length

- %Coating

- %Material

By configuring more tokens, you can have a more precise mapping. If the default is configured, for example, only with the token %Norm, and then you can have only one mapping definition line where you map the bolt class name to an external name, without the option to map multiple diameters, materials etc. of that bolt class name to multiple external names.

Mapping configuration

In this section we will configure the mapping relations between the bolt name given by Advance Steel and the custom external name which we need to display in BOM lists and labels.

The mapping is done in the AstorAddIn database, as Advance Steel prioritizes this table over the AstorBase database table which stores by default many mappings (for example for flat profiles).

To configure the mapping, open the AstorCurrentAddIn database with the Management Tools Table editor, and then open the table called MapInternToExtern.

The table cells associated to a new entry are as follows:

- Key : Unique number. If there are multiple lines that contain the same Internal name mapping, then Advance Steel will consider the one with the lowest Key number.

- Internal - It needs to be filled with the original name, the one that requests the mapping. The format of this entry needs to match the attributes set in the Priority default.

- External 1 - 4 - these four column cells contain the external name to which the bolt name is mapped. Each of them has a token associated for configuration. The unconfigured cells can remain empty.

- Description - free text for user description about a specific mapping. The information in this field does not have an option to appear in Advance Steel documents.

- Owner Text - mapping owner.

The names used as a source for mapping (in the Internal column) must be internal names, and not the ones that come from the "RunName" value in source tables.

The names used as a source for mapping (in the Internal column) must be internal names, and not the ones that come from the "RunName" value in source tables.

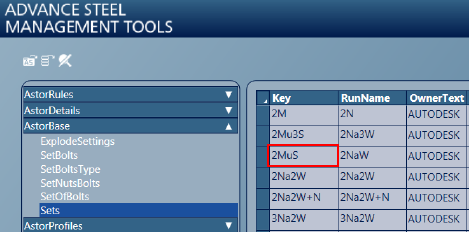

For example, when we refer to the bolt assembly, we need to use the internal name which for a specific bolt assembly can be found as follows: Open the AstorBase database and go to the Sets table.

The internal name is found in the Key column, while in the RunName column we have the interface name for that specific set. For example the 2NaW set has as internal name 2MuS.

Mapping configuration example:

Bolt that requires mapping:

- Name: 6914

- Material: 10.9

- Set: Na2W

- Diameter: 12mm

The configuration requires to:

Set the mapping priority default first to %Norm %Material %Set %Diameter

Add a new line to the MapInternToExternal table as follows: Internal: 6914 10.9 Mu2S 12External1: name used for mapping, for example 6914-M12X

Label configuration

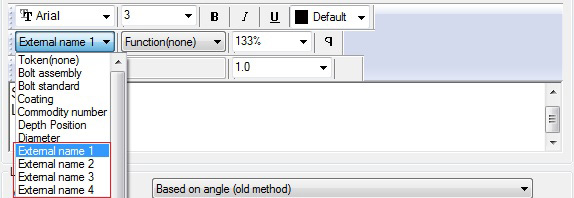

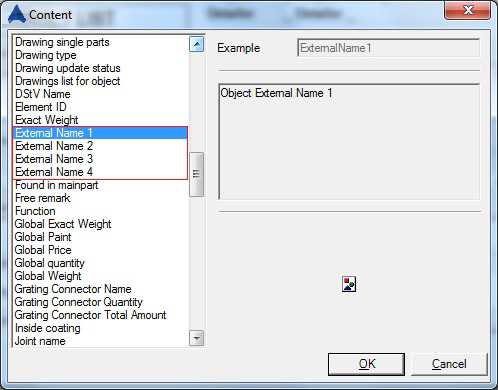

The mapped information from the External1 - 4 columns can be displayed in BOM templates and drawing (labels, detail names) through a series of contents / tokens named External 1 - 4 and they evaluate the respective column information if the object they are attached to corresponds to the mapping priority and value preset in the "Internal" column.

BOM template contents:

Drawing style label editor: