Construction Tolerances determine how accurately matched your surfaces are in your model, and are selected using Preferences > Construction Options.

Surfaces built to the right tolerances won't have any 'gaps' between surface patches that are meant to describe a continuous shape. This is important for creating 'water-tight' models that can be exported into Engineering CAD systems or for prototyping or manufacture.

Construction Tolerances cannot be applied after the geometry is created, they need to be set before you start to build the model.

Applying the Rule

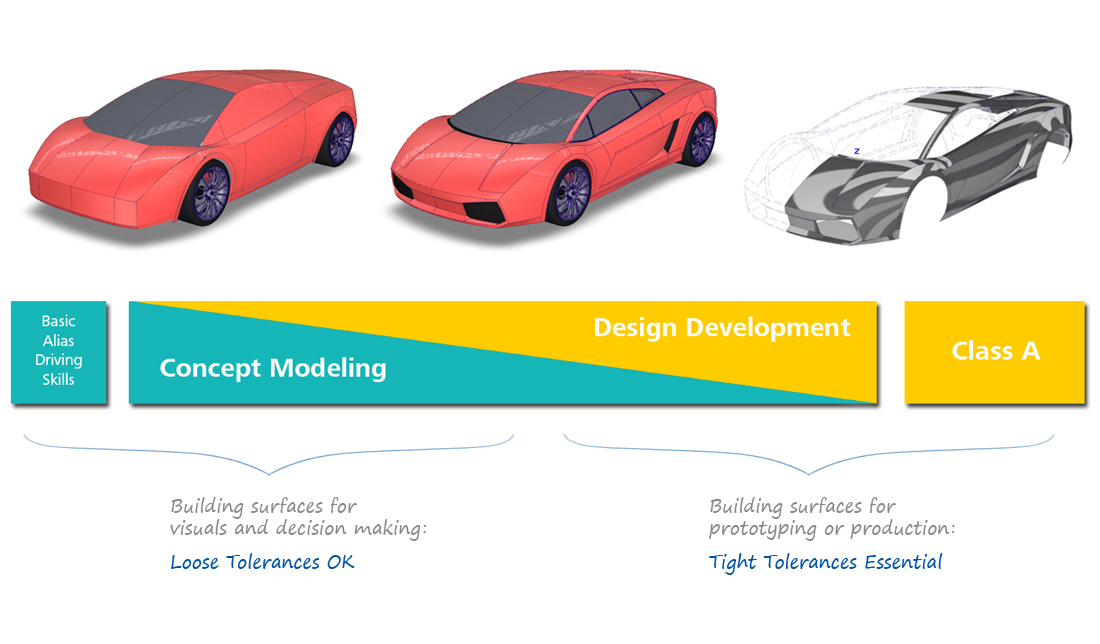

Using tight Construction Tolerances is more important later in the design process:

Breaking the Rule

You can ignore the tolerance settings if you are:

- Just practicing your Alias skills, for example doing the Fundamentals Skill Builders.

- Creating models for rendering and animation only.

Theory and Practice

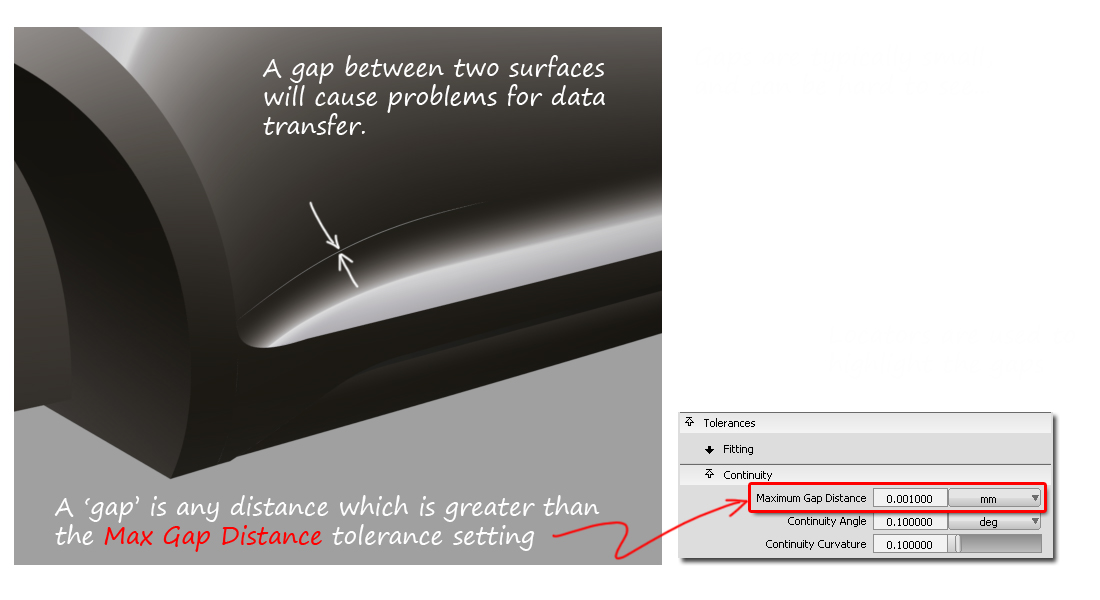

Maximum Gap Tolerance

There are many different Construction Tolerance settings which can be selected in the Preferences > Construction Options window.

The key setting for data transfer is the Maximum Gap Distance.

Why not set the tolerances to the tightest possible settings?

Each surface tool (Skin, Rail etc.) or operation (Intersect, Trim, Align etc.) refers to the Construction Tolerance settings to determine how accurately to be applied. Greater accuracy can lead to longer calculation times, so try to select the right settings for the stage of work that you are at.

As you gain production experience with Alias, you will become more confident in choosing how and when to apply different tolerance settings. As a beginner, the easiest choice is to use one of the Construction Pre-sets (see below).

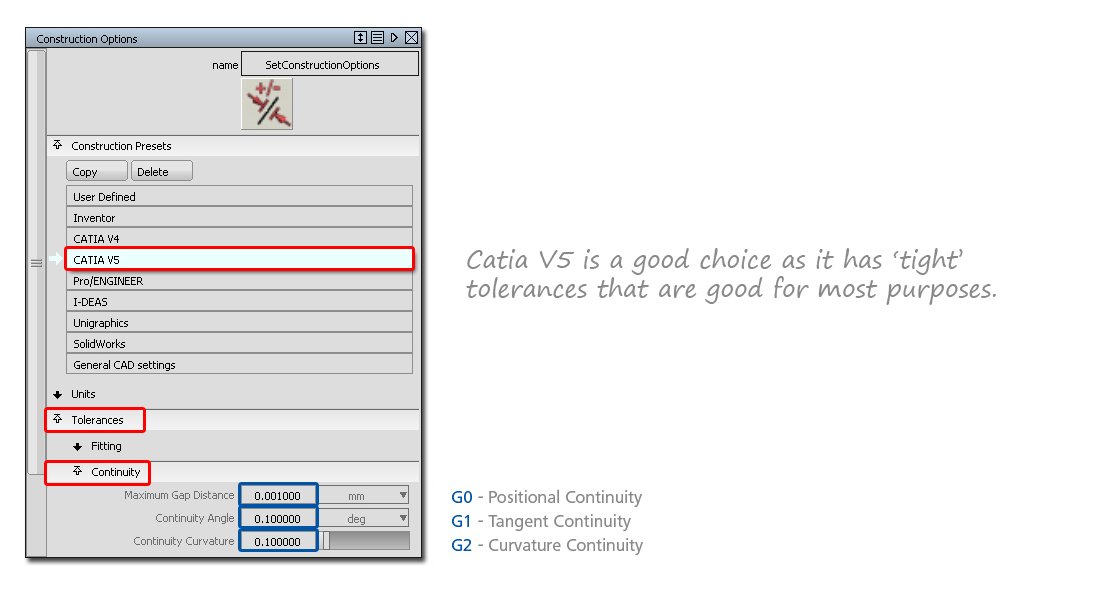

Using Construction Presets

Use Preferences > Construction Options to set the construction tolerances for creating surfaces.

The first section is the Construction Presets. These set the typical tolerances required for exporting out to the most common CAD systems, and are the easiest way to choose your modeling tolerances.

Further Information on Construction Tolerances

For more detailed information on construction tolerances:

- Continuity 2: Construction Tolerances Theory Builder

- Preferences > Construction Options (Alias Help)