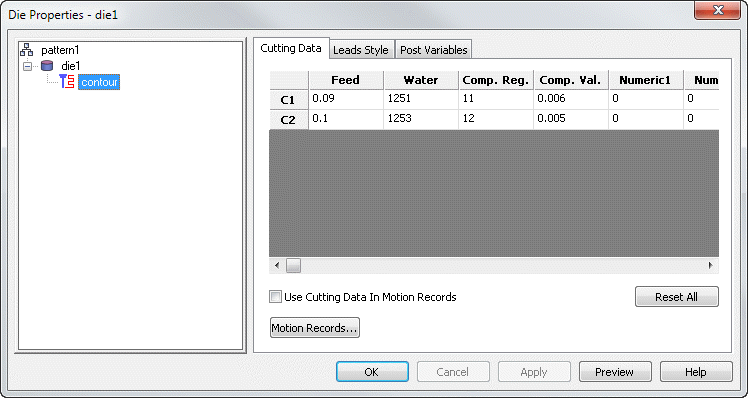

In the example above, C1 is the first pass and C2 is the second pass.

Feed is the feed rate.

Water is where you enter your EPAK values. For an EPAK value of E1251, enter 1251.

Note: You should have documentation with your machine that lists the EPAK values for various materials and thicknesses. So, for example, it should give you one EPAK value for 0.5 inch thick aluminum, another for 0.75 inch aluminum, another for 0.5 inch titanium, and so on. Each EPAK contains settings for 'On Time', 'Off Time', 'Dwell', 'Voltage', and so on.

Comp. Reg associates each Comp. Val with a particular pass and appears as H11, H12, and so on in the NC code.

Comp. Val is basically the wire radius plus the wire offset. Comp. Vals should also be in your machine's documentation.

Here is the NC code for the above example, with the values from the table marked in bold:

N10 G90 N15 M101 N20 M106 Q-2 N25 G53 G92 X-95.956 Y-61.722 Z0 N30 M20 (WIRE THREAD LN) N35 M78 ( FILL TANK ) N40 M78 N45 M80 ( FLUSHING ON ) N50 M82 ( WIRE FEED ON ) N55 M84 ( MACHINING ON ) N60 M90 ( ADAPTIVE CONTROL ON ) N65 H11=0.006 N70 E1251 F0.090 N75 G01 G42 X-369.727 Y-348.437 H11