For a relatively rare number of geometries, the tool axis can waver slightly as it positions accurately on the surfaces to be machined. This can be due to small but significant changes in the geometry as the tool moves from one position to another. This tolerance can be larger than the machining tolerance to stabilize the tool axis as it moves across this geometrically varying region. As a consequence excess material may be left on the surface but the load on the tool may be reduced.

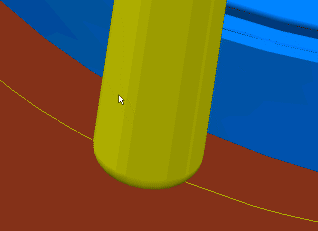

No Axial tolerance set:

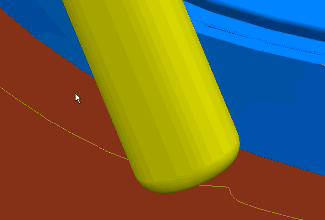

Axial tolerance set to 0.5 (mm):