Select core/cavity uses surface orientation to extract surfaces for the core or cavity portion of a mold.

It segregates the surfaces of a solid into one of three different types.

We recommend using the Automatic split option. This option splits the faces of the solid at either the silhouette of the solid, or along a parting surface that you provide as the Part Srf. With the Part Srf option set to **Automatic, the silhouette curve is automatically calculated and used to split the faces before the classification into the top, bottom or other category.

If you specify a parting surface for the Automatic splitting, this surface must pass all the way through the solid.

To select a core/cavity:

- Select Construct tab > Solids panel > Manufacturing > Core/Cavity to display the Select Core/Cavity dialog.

- Choose whether to you want to Select the Bottom, Top, or Other surfaces.

- Select the name of a solid from the

Solid list or click the

Pick solid

button and

select the solid in the graphics window.

button and

select the solid in the graphics window.

- The silhouette curves are determined from the +Z direction of the UCS. Select the appropriate UCS from the UCS list.

- If there are surfaces you want to exclude, click the

Pick surface

button, select the surfaces in the graphics window and click the

Add

button, select the surfaces in the graphics window and click the

Add

button.

button.

- If you want to include the vertical surfaces, select Include vertical surfaces.

- Optionally select Make solid from result.

- If you want to split the surfaces at the silhouette curve, check Automatic split and leave the Part srf field set to **Automatic.

- If you want to split the surfaces at a parting line check Automatic split and set the Parting surface field to the name of the parting surface.

- Click OK.

The appropriate surfaces are now selected so that you can easily create 3D surface milling features.

Original example

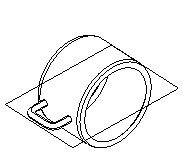

Top

All surfaces (or portions of surfaces if the Automatic Split option is enabled) that are visible from the top.

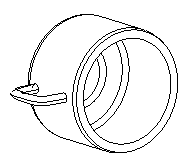

Bottom

All surfaces (or portions of surfaces if the Automatic Split option is enabled) that are visible from the bottom.

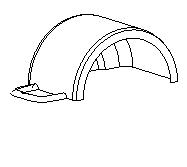

Other

All surfaces that do not fall into either the top or bottom category. These surfaces are usually referred to as the core.