Corner correction defines the type of corner correction that you want to apply to all internal corners of a Z-level finish toolpath. The types are available from a pull-down list and three options are available:

None - no sharpening or arc fitting is carried out.

Arc Fitted - arcs are created and rounded in all internal corners.

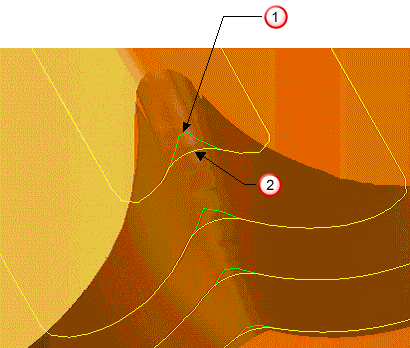

The yellow toolpath shows the Arc Fitted toolpath and the green toolpath shows the Normal toolpath.

Arc fitting is of particular importance when high speed machining, as it eliminates sudden changes in tool direction.

- Normal

- Normal

- Arc fitted

- Arc fitted

Corner Radius %

This defines the radius used if you select Arc Fitted. The radius is defined as a proportion of the tool diameter. For a Z finish pass the default value is 5%. So, if you have a tool of diameter 10 mm (radius 5 mm) then the arc radius is 0.5 mm. The Corner Radius% can have a value between 0 and 100.