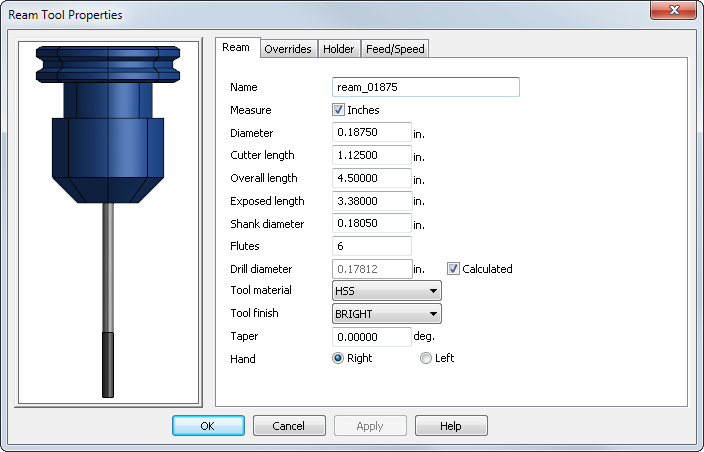

Ream tools are used for reaming operations on holes.

Name — Enter a name that identifies the tool. The name must be unique among all the tools in the crib.

Measure — This indicates the units that are used for reporting the tool’s dimensions. Select Inches for inch units or deselect it for millimeters.

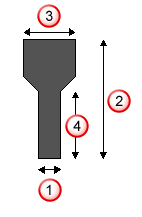

Diameter — See diagram.

Cutter Length — See diagram.

Overall Length — See diagram.

Exposed length — This is the amount of the tool that sticks out of the holder if the holder is simulated.

Shank diameter — See diagram.

Drill diameter — Enter the default diameter of all drill and bore tools used in the feature. This value should not be larger than the Diameter value of the tool, as this causes the drill tool to be larger than the ream tool, which may compromise the accuracy of the feature. If Calculated is selected, the Drill diameter is calculated from the Drill % of ream/bore attribute on the Tool Selection page of the Machining Attributes dialog.

Tool material — This indicates what the tool is made of. This information is important when calculating the feeds and speeds.

Tool Finish — This is the coating, or finish, on the tool. This information is also used in feed/speed calculations. If a feed/speed table exists for a material cut with a tool with a Bright finish, but not for TI_N or Black Oxide tool finishes, then the speed values are derived from the Bright table. The speed for TI_N is 1.5 times the BRIGHT speed. The speed for BLACK_OXIDE is 1.05 times the BRIGHT speed. The feed rates are the same as the BRIGHT feed rates.

Hand — Set whether the tool is Right-handed or Left-handed.

|

|

|

Diameter

Diameter

Overall Length

Overall Length

Shank Diameter

Shank Diameter

Cutter Length

Cutter Length