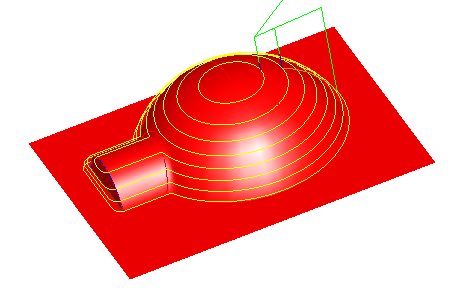

Continuous spiral — Enable this option to stop the tool lifting from the surface when machining.

Enable Continuous spiral to have a toolpath that stays in constant contact with a surface, reducing the chance of leaving any dwell or witness marks on the surface caused by regular retract and approaches to the surface.

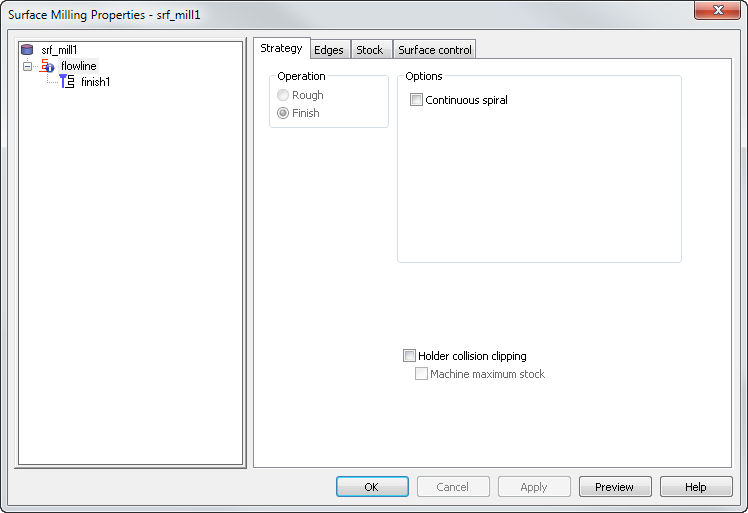

The standard Z level finishing toolpaths creates paths with a constant Z height as shown below. The tool either retracts or feeds along the surface between Z levels.

With Continuous spiral enabled, the toolpaths change into a continuous spiral. The toolpaths no longer have a constant Z height.

Holder collision clipping — Clips the toolpath where the holder or shank collides with a part surface, check surface, or unmachined stock. When selected, the Holder clearance and Shank clearance attributes are displayed on the Milling tab for the operation.

Machine maximum stock — Use with Holder collision clipping to machine the stock as close to the part without causing a holder collision. This creates smoother toolpaths with fewer retracts, which can improve the surface finish and reduce the machining time, but may cause increased air cutting on some parts.