Pre-drill differences

There are some differences with how the Pre-drill operation works with the NT toolpaths compared to the traditional toolpaths.

- You can use a Pre-drill operation with the NT Zigzag toolpath. It is not available for the traditional Zigzag toolpath.

- With the NT toolpaths, zigzag ramping is automatically disabled when you use a Pre-drill operation. This is not supported for the original Spiral toolpath and you must set the Max. ramp angle to 0 to disable zigzag ramping when using a Pre-drill operation.

- The Pre-drill operation for the NT toolpaths includes the tops of multi-height islands (not supported for the original toolpaths).

- The traditional Spiral toolpath supports manual plunge points for the pre-drill locations using the Plunge point(s) attribute. The NT toolpaths support only automatic locations.

Stepover differences

There are some differences in the attributes available for NT toolpaths on the Stepover tab of the Feature Properties dialog:

There are two Ramp type options for the NT toolpaths:

- Smooth — This is similar to the traditional toolpath option S-type

- Direct — This is similar to the traditional toolpath option Line.

You can specify separate Lead-in and Lead-out options for NT toolpaths:

The NT toolpaths have an Approach from outside option. This option automatically adds a small lead-in whenever the tool is plunging off the stock. When you select this option, the lead-in options are disabled. Deselect it to manually specify the lead-in as a line, arc, and/or toolpath extension.

Pocket feature:

For a Pocket feature, the toolpath slot cuts following the offsets instead of just a straight line. There are fewer plunges than with traditional toolpaths.

Traditional toolpath example:

NT toolpath example:

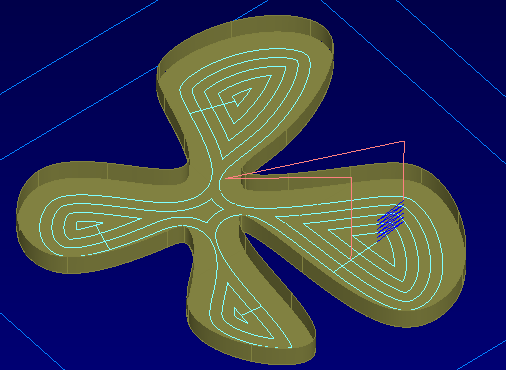

Boss feature:

For a Boss feature, the toolpath has a lot fewer retracts and plunges at the edge of the Stock.

Traditional toolpath example:

NT toolpath example:

Other differences

On the Milling tab, NT toolpaths have a Stepover rapid distance attribute, which controls when to retract and plunge on Boss stepovers. This is an absolute distance and replaces the Min. rapid distance % attribute used by the traditional toolpaths.

You can use the Output Options dialog to control how the points of a toolpath are processed in the NC program. For 2.5D features, this dialog is only available for NT toolpaths.

Using the Minimize tool retract options with the NT toolpaths gives better results than with the traditional toolpaths.