Z-level roughing can be performed with multiple tools. After a larger tool is used to rough out the majority of the part, FeatureCAM can automatically apply a semi-roughing pass to the uncut regions of the part without recutting the previously roughed region. The smaller tool roughs around the walls of the part with a smaller Z- increment than the previous tool and roughs regions where the larger tool does not fit.

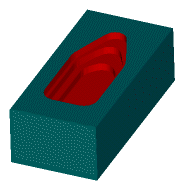

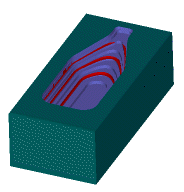

This example shows a bottle that is first roughed with a 0.75 inch endmill and then roughed with a 0.25 endmill:

Roughing with multiple roughing tools is much more efficient than simply roughing with a small tool. In the case of the bottle, roughing with two tools takes 9 minutes and 34 seconds, while roughing the entire part with only the smaller tool takes 19 minutes and 8 seconds.

To perform Z-level roughing with multiple tools:

- On the Strategy tab of the New Feature wizard or the Feature Properties dialog, select the Multiple rough option.

- Enter a list of Tool diameters. Separate the diameters with a comma. Each diameter must be smaller than the preceding diameter.

Each of the roughing passes is listed in feature's tree view so you are able to further edit these operations to customize attributes such as stepover values or Z increments.