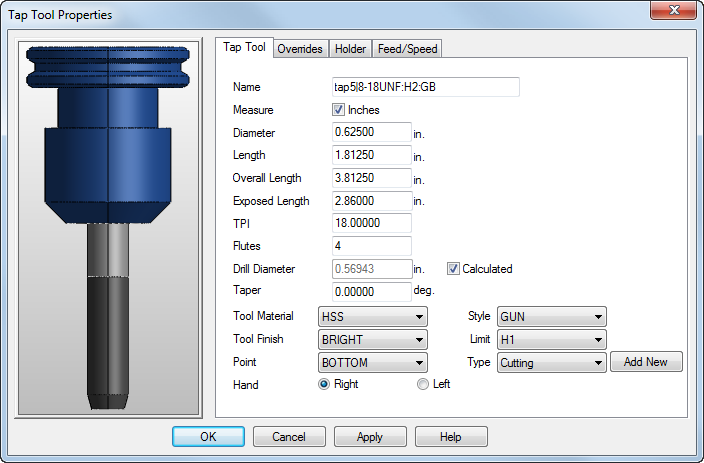

Tap tools are used to tap holes.

Name — Enter a name that identifies the tool. The name must be unique among all the tools in the crib.

Measure — This indicates the units that are used for reporting the tool’s dimensions. Select Inches for inch units or deselect it for millimeters.

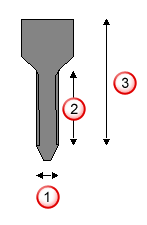

Diameter — See diagram.

Length — See diagram.

Overall Length — See diagram.

Exposed length — This is the amount of the tool that sticks out of the holder if the holder is simulated.

TPI/Pitch — For inch tools, you specify the threads per inch (TPI), and for metric tools, you specify the Pitch of the threads.

Drill Diameter — If this is set, that tap always uses a twist drill of that diameter. If you select Calculate, the drill is calculated using the product's formulas. FeatureCAM uses one of two formulas for calculating Drill Diameter. One formula is used for Cutting, Helicoil, and user-defined tap types. The other formula is used for Rolled types. You can control these two formulas by using the Thread % for tap drill (cut) and Thread % for tap drill (rolled) attributes on the Tool Selection page of the Machining Attributes dialog.

If no Drill Diameter is set for helicoil or user-defined tap types, then the cutting tap formula is used to calculate the drill diameter.

Taper — If you want a tapered tap, enter the angle in degrees. Holes with tapered threads automatically select tapping tools with the same taper angle.

Tool material — This indicates what the tool is made of. This information is important when calculating the feeds and speeds.

Tool Finish — This is the coating, or finish, on the tool. This information is also used in feed/speed calculations. If a feed/speed table exists for a material cut with a tool with a Bright finish, but not for TI_N or Black Oxide tool finishes, then the speed values are derived from the Bright table. The speed for TI_N is 1.5 times the BRIGHT speed. The speed for BLACK_OXIDE is 1.05 times the BRIGHT speed. The feed rates are the same as the BRIGHT feed rates.

Point — Bottom taps have a flat bottom, and Plug taps come to a point. If a bottom tap is required for a blind hole, a warning is issued in the operations sheet. Regardless of the type of tool used for tapping, the hole must allow enough clearance for the tap. If the hole breaks this rule, an error message is generated when you enter the hole dimensions.

Style — Spiral-style taps have twisted flutes while Gun-style taps have straight flutes.

Limit — This attribute is ignored for tool selection. It is used only to document the tool.

Type — A tapped hole is classified by its Type. When selecting taps, FeatureCAM searches for a tapping tool that matches the Type of the threaded hole.

- Cutting — These tools cut the threads into the material. The diameter of the drilling operation is typically calculated.

- Rolled — These tools press or form the threads into the material. The diameter of the drill operation for rolled (or formed) taps is typically larger than for cutting taps and is typically calculated using a formula.

- Helicoil — These operations are performed within a cutting-style taps, but the size of the drill and tap operations are larger to fit the helicoil insert. For these holes, specify the TPI and Diameter of the helicoil that you want to insert and FeatureCAM selects the appropriate drill size and helicoil tap.

Add New — New types can be created when a tapping tool is defined. Any new tapping tool type is displayed as a potential hole tap type. Automatic tool selection is limited to looking for tools of this new type.

Hand — Set whether the tool is Right-handed or Left-handed.

|

|

|

Diameter

Diameter

Length

Length

Overall Length

Overall Length