You can use the Round Stock page to edit the settings which affect Turning and Turn/Mill simulations.

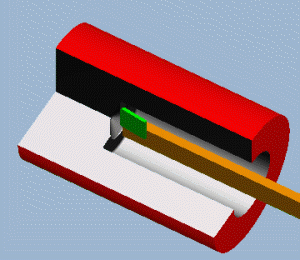

3/4 view with lathe ID work — This option enables a 3/4 cut-away view for ID work for turned setups.

Roundness tolerance — Reduce the tolerance to make round stock appear rounder and less faceted.

|

Higher Roundness tolerance:

|

Lower Roundness tolerance:

|

Turn/mill angular interpolation — If the part rotates during cutting, the movement of a point on the part's surface is approximated with small linear movements instead of a true circular movement. This setting determines how accurately the linear movements approximate the actual movement of the part. Increase this setting to reduce the simulation time for complex parts. This tolerance is also affected by the wrapping tolerance and linearization attributes.

Chip recognition size — During simulation, detached pieces of the part are removed if they are smaller than this value. For parts with large stock, you may want to reduce this value to ensure cutoffs are not hidden.

Swiss

Move bar clamp based on part length — For Swiss documents, this enables the bar clamp to move along the stock if necessary, such as to expose a large length of stock past the guide bushing. If this is deselected, the bar clamp is simulated in the location specified in the Machine Design file.

Extend Stock to Bar Clamp — During simulation, extend the stock length so it is long enough to reach the bar clamp.