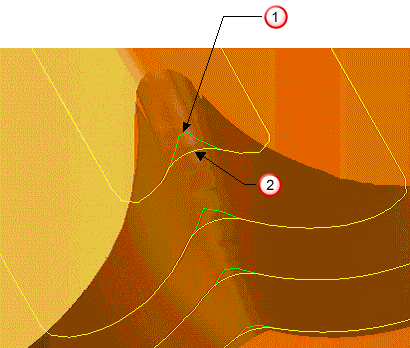

Slices in Z-level (both rough and finish) can be arc-fitted to avoid sharp changes in direction. For Z roughing, only the toolpath closest to the part is rounded. Corner radius % defines the radius that is inserted in to the toolpaths.

The radius of internal corners is defined as a proportion of the tool diameter. The default value is 5% for a finish pass and 0% for a roughing pass. So if you have a tool of diameter 10 mm then the arc radius is 0.5 mm. The Corner radius % can have a value between 0 and 100.

Arc fitting is of particular importance when high speed machining as it eliminates sudden changes in tool direction.

- Normal

- Normal

- Arc fitted

- Arc fitted