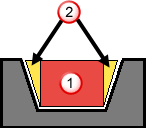

Plunge center first — For groove features, if this option is selected, the straight portion of the groove is roughed first and then the angled portions are roughed separately.

If Plunge center first is set, the red rectangular center region is roughed first and then the two angled regions along the walls.

Feed direction — This is the direction the tool feeds. The choices are either Toward spindle / Negative X or Toward Face / Positive X. For finish, you can also set this to Opposite from rough direction.

Side liftoff angle — Enter the angle to lift the tool off the part after each plunge cut. This increases the tool's life and leaves a better finish on the part. This attribute applies to a Groove feature.

Side liftoff dist — Enter the distance to move the tool after a plunge cut, in the direction opposite to the cutting direction. This increases the tool's life and leaves a better finish on the part. This applies to a Groove feature. See also Side liftoff angle.

Dwell — The number of seconds the tool dwells after plunging during a groove roughing pass.

Use 2nd offset register — Use a different offset register for each side of a grooving tool. The second offset register number is displayed in the Tool Mapping dialog.

Stepover — Enter the distance, as a percentage of the tool's diameter, that the tool shifts to position itself for the next plunge cut. This value specifies the maximum stepover distance. If this value evenly divides the width of the feature, it is used. If it results in a final pass that is quite shallow, the cut widths are adjusted to result in even roughing passes.

For example if you have a feature that is 0.5 inches wide and specify a width of cut of 0.4 (specified as a Stepover % of 80 for a tool with a diameter of 0.5 inches), the feature is roughed in two even passes 0.25 inches wide rather than one pass of 0.4 inches and another pass with a width of 0.1 inches.

Chamfer extend dist — This provides extra space for the tool so that the tool does not start on the material for the Groove finish pass.

Peck retract dist. — For Cutoff and Groove features, Peck retract dist is the distance the tool retracts between plunges.