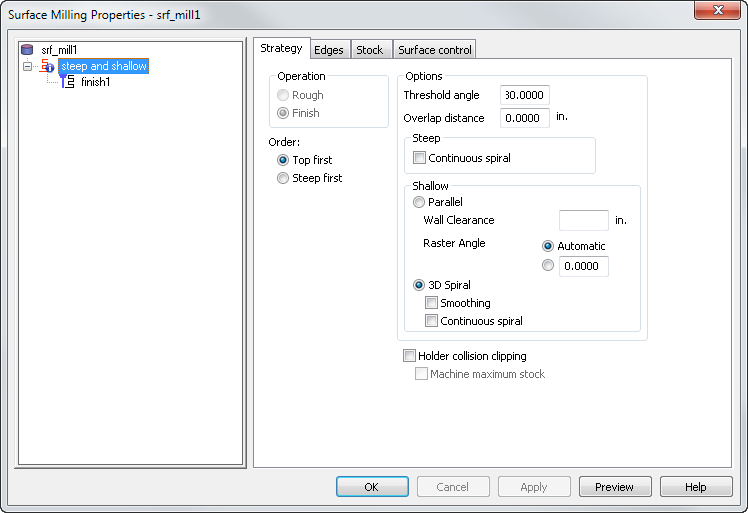

Order — This determines the order in which the steep and shallow portions are machined.

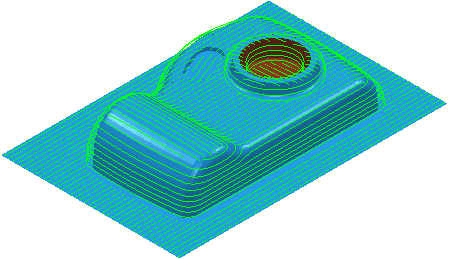

- Top first — Select this option to machine from the top regions downwards. If you have a boss, the shallow regions at the top of the boss are machined before the steep regions down the sides.

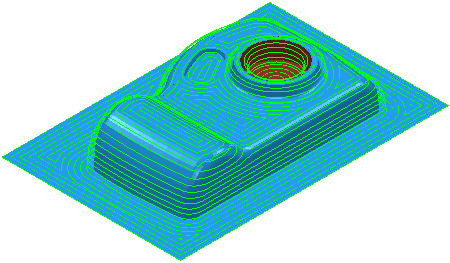

- Steep first — Select this option to machine the steep sections before the flat. If you have a boss, the steep regions are machined before the shallow regions.

Options

Threshold angle — Enter the angle of the surface slope, measured from the horizontal, that determines the split between constant Z (steep) and shallow machining.

Overlap distance — Enter the size of the overlap area between steep and shallow machining. This reduces marks on the model caused by a sudden switch between steep and shallow machining.

Steep

Continuous spiral — Select this option to create a spiral path between two consecutive closed contours. This minimizes the number of lifts of the tool and maximizes cutting time while maintaining more constant load conditions and deflections on the tool.

Shallow

Select from:

Parallel

Optionally enter a Wall Clearance and Raster Angle.

3D Spiral

Smoothing — Select this option to smooth offsets of toolpath segments over the model.

Holder collision clipping — Clips the toolpath where the holder or shank collides with a part surface, check surface, or unmachined stock. When selected, the Holder clearance and Shank clearance attributes are displayed on the Milling tab for the operation.

Machine maximum stock — Use with Holder collision clipping to machine the stock as close to the part without causing a holder collision. This creates smoother toolpaths with fewer retracts, which can improve the surface finish and reduce the machining time, but may cause increased air cutting on some parts.