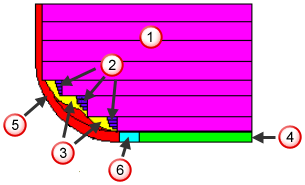

Features with a bottom radius are manufactured with some combination of the operations shown below.

- The Rough pass cuts starting at the top and either roughs down to the bottom of the feature (if you are not finishing the bottom) or leaves a finish allowance at the bottom.

- The stair steps of the roughing operation are knocked down by the Draft flat operation. This operation takes only a single pass at each Z level.

- The stair steps of the Draft flat operation can be further smoothed by the Draft radius operation. This operation also takes only a single pass at each Z level.

- If the bottom of the feature is finished the Flat bottom operation is performed next with a flat-end mill.

- The bottom radius and the walls of the feature are finished by the Finish pass.

- If the feature has a tight corner on the floor that could not be finished by the flat bottom operation, a Corner operation is performed.

|

|

|

Rough pass

Rough pass Draft flat

Draft flat Draft radius

Draft radius Flat bottom

Flat bottom Finish pass

Finish pass Corner

Corner