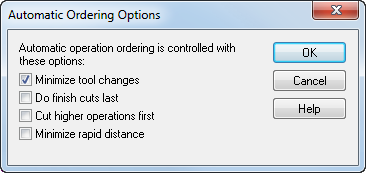

The following settings control the ordering of milling operations.

Minimize tool changes — This option groups operations together that use the same tool. This saves time for you by eliminating or reducing needless tool changes. You must select this option if you want to generate hole macros in the NC code.

Do finish cuts last — This option moves the finish milling operations to the end of the Setup without altering the order of the finishing operations. If you want to perform all rough milling operations before finish milling operations, select this option.

Cut higher operations first — This option affects only milling Setups. Select this option to mill the features from the top of the stock first and work toward the bottom. If you deselect this attribute, you should carefully graphically verify the toolpath before cutting your part.

Minimize rapid distance — This affects only milling Setups and is the only ordering option that changes the order of features specified in the part view. Minimize Rapid Distance moves to the next closest feature that uses the same tool as the last operation. You must deselect this option if you want to generate hole macros in the NC code.

If you have selected all of the optimization options, the manufacturing order for operations that were derived from different features is determined like this:

- The operations are sorted by their top Z coordinate.

- Among operations with the same top Z coordinate, operations are grouped by the tool with which they are cut.

After an operation is cut, FeatureCAM moves to the next operation performed with the same tool that is the closest to the current operation.