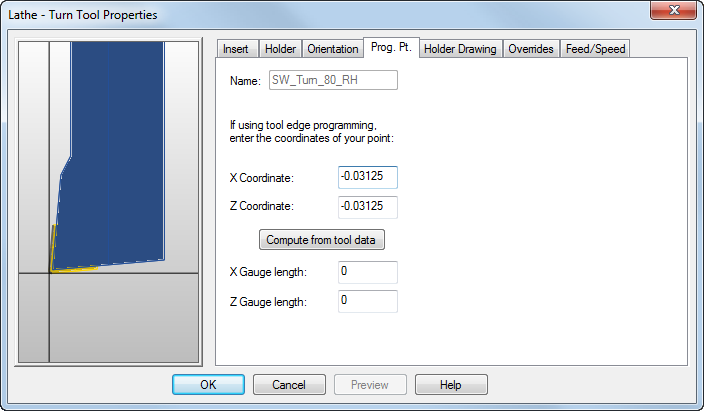

On the Prog. Pt. (program point) tab you set the point of the insert that is programmed. You can set both the X Coordinate and the Z Coordinate.

Click the tool preview image to pan and zoom it. The orientation of the preview is determined by the settings on the Options > View > Machine page. Right-click the image to access a context menu.

Name — Specifies the name of the current tool.

Tool tip center — If both X Coordinate and the Z Coordinate are set to 0.0 then the center point of the tip arc is programmed. In this case it is expected that you perform insert radius compensation at the machine tool.

Tool tip edge — To perform insert radius compensation in FeatureCAM, set the X Coordinate and Z Coordinate to the radius compensation values provided with your tool.

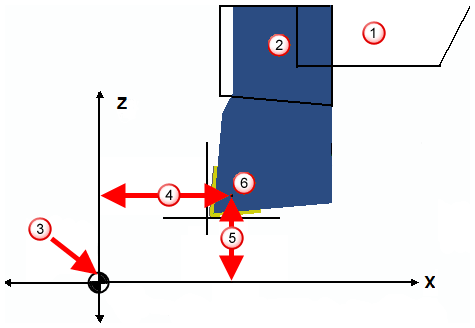

X/Z Gauge length — This is the distance between the tool program point and the origin/part program zero in the X and Z directions, when the tool is at the tool home/tool change location position:

|

|

|

X Gauge length corresponds to the <X-PRESET> reserved word in XBUILD.

Z Gauge length corresponds to the <Z-PRESET> reserved word in XBUILD.

Turret

Turret

Holder

Holder

Origin (0,0)/Part program zero

Origin (0,0)/Part program zero

X Gauge length

X Gauge length

Z Gauge length

Z Gauge length

Tool program point

Tool program point