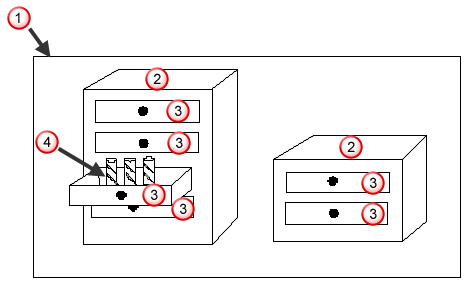

For each manufacturing operation created for the features of a part, a tool must be selected from the internal tooling database. This database is broken into separate tool cribs to represent individual collections of tools that your organization might have. The image below shows the structure of the tooling database.

|

|

|

FeatureCAM comes with two different built-in tool cribs. The Basic crib is the default crib that contains standardly available tools that most shops own. The Tools crib is a large crib containing thousands of tools. This crib is most often used as a source to copy from into custom tool cribs or into the basic tool crib. Only one tool crib is available at a time and all tools are selected for a part from only the current tool crib. Tool cribs contain individual tools and they are classified into tool groups such as drills, end mills, and boring bars. You cannot create new tool groups, but you can create new tools to reflect the specific tools that your shop owns.

Each feature type has rules for tool selection.

Double-click a feature in the graphics window or the Part View panel to display the Feature Properties dialog, then select an operation from the Tree View on the left of the dialog.

On the Tools tab of the Feature Properties dialog, you can:

- see which tool is currently selected to perform the operation; or

- change the tool used to perform the operation.

Tooling database

Tooling database

Tool cribs

Tool cribs

Tool groups for example drills, taps, or mills

Tool groups for example drills, taps, or mills

Tools

Tools